Bespoke Stillages & Custom Stillage Solutions

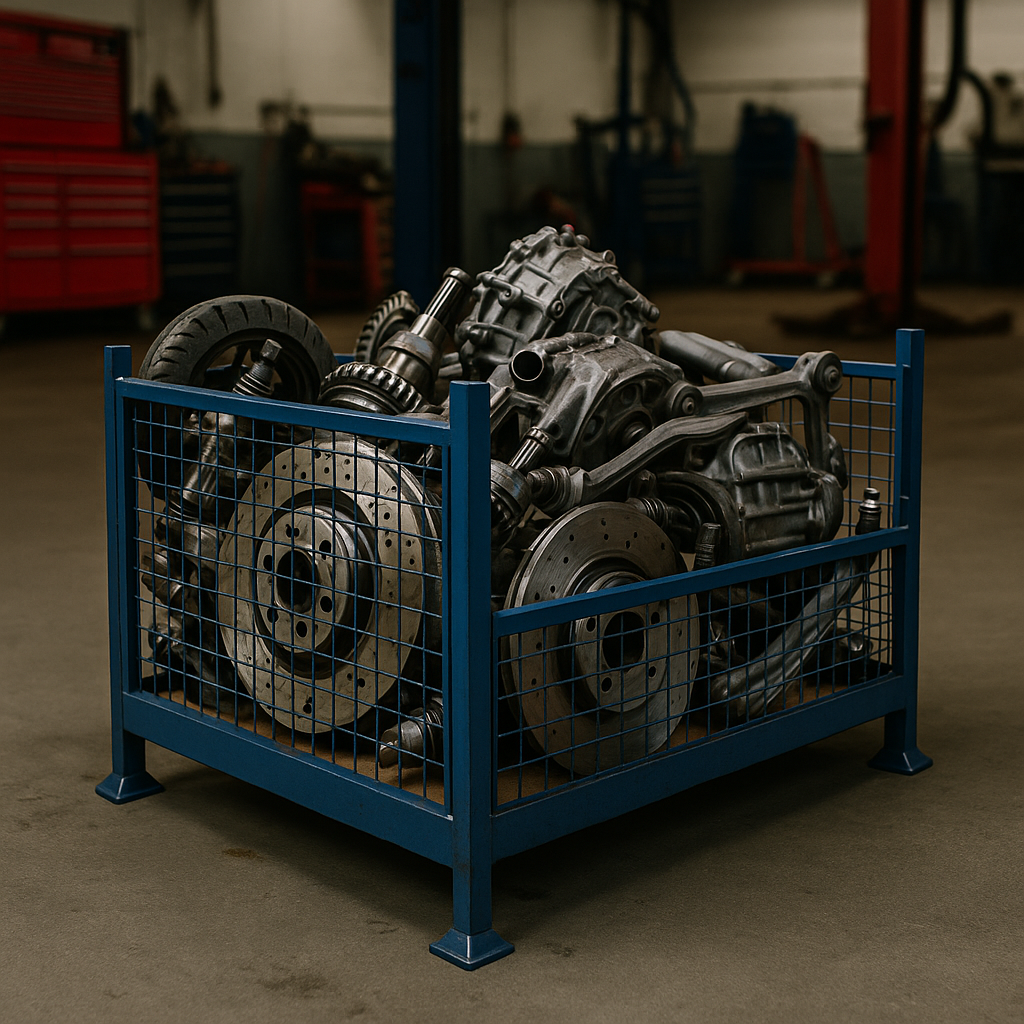

Our bespoke stillages serve every sector. From construction and civil engineering (for storing pipes, rebar, formwork and panels) to automotive and manufacturing (handling assemblies, panels and tooling) to warehousing and logistics (storage trays, picking frames, parcel cages), Lowe stillages fit the bill. We build solutions for niches like glass & curtain walling (window frames, façade panels), gas and utilities (cylinder stillages, bottle cages), furniture and bedding (mattress and bed-frame stillages) and more. In fact, stillages are adaptable to any industry where secure, efficient material handling is needed. If a requirement isn’t shown on our site, our team can design and build it to your needs.

Custom Stillages for Any Industry

Our bespoke stillages serve every sector. From construction and civil engineering (for storing pipes, rebar, formwork and panels) to automotive and manufacturing (handling assemblies, panels and tooling) to warehousing and logistics (storage trays, picking frames, parcel cages), Lowe stillages fit the bill. We build solutions for niches like glass & curtain walling (window frames, façade panels), gas and utilities (cylinder stillages, bottle cages), furniture and bedding (mattress and bed-frame stillages) and more. In fact stillages are adaptable to any industry where secure, efficient material handling is needed. If a requirement isn’t shown on our site, our team can design and build it to your needs.

Precision-built to your exact specifications:

We fabricate every stillage in our UK facility, giving you complete flexibility on dimensions, weight capacity, layout and access features. This means you can choose solid or mesh floors, removable posts, castors or forklift pockets, and any custom design needed for your products.

Heavy-duty construction for demanding environments:

Each stillage is made from structural steel with reinforced welds, so it can withstand daily use, heavy loads and harsh industrial conditions. Our robust construction ensures your stillage will last in even the toughest warehouses or worksites.

Optimised for your product, process and space:

We tailor every detail of the stillage around your handling process. Whether you need stacking, racking, storing or transporting components, a custom design maximises space efficiency and safety. In fact, custom stillages can greatly improve space saving and protect goods during storage and transport.

Full design support:

Our team works with you from basic sketch through full CAD drawings and prototypes. We consider safe working loads, lifting requirements and ergonomic access to create the right solution for you. This means even complex requirements like lifting points or load testing are integrated into the design.

Flexible finishes:

Finish options include self-colour, any RAL/BS paint or full galvanising and we offer powder-coating for extra corrosion protection or high-visibility. Custom branding plates or colour-matched paint can also be added so the stillage fits your corporate look or environmental needs.

How Our Bespoke Stillage Process Works

Consultation & Requirements:

Share your dimensions, weights, material drawings or sketches. We discuss your usage conditions and assess any special requirements (access points, lifting, ergonomics).

Design & CAD Development:

Our engineering team uses in-house CAD to develop a tailored concept. Within about 1–2 weeks we present a design concept for your approval, ensuring safe working loads and efficient handling are built in.

UK Manufacturing:

Once approved, we build the stillage in our UK facility. In-house production gives us full control over quality, lead time and material selection and allows us to weld and assemble everything precisely to spec.

Delivery & Repeat Production:

After factory acceptance, we deliver your bespoke stillage. If you later need more units, we can produce additional batches quickly to the same high standard, ensuring consistency across the entire run.

Finishes & Customisation Options

Our stillages can be customised with features such as:Mesh, solid sheet or open sides (for visibility or protection)

Fork pockets, crane lifting points or castors (mobility and lifting)

Hinged, drop-front or removable side panels (easy access)

Collapsible/demountable frames (save space when not in use)

Removable dividers and internal supports (for organising contents)

Heavy-duty flooring (wire mesh, steel plating or reinforced deck)

Branding plates and colour-matched paint finishes (for identification or aesthetics)

Galvanised or powder-coated surfaces (for corrosion resistance and durability)

Looking for quality stillages and cages that are built to last?

Look no further than Lowe Stillages and Cages! As a British manufacturer, we take pride in crafting each product using only the highest-quality materials. We manufacture a wide range of products, including custom products built to your specification.