CAD & 3D Printing at Stillages & Cages

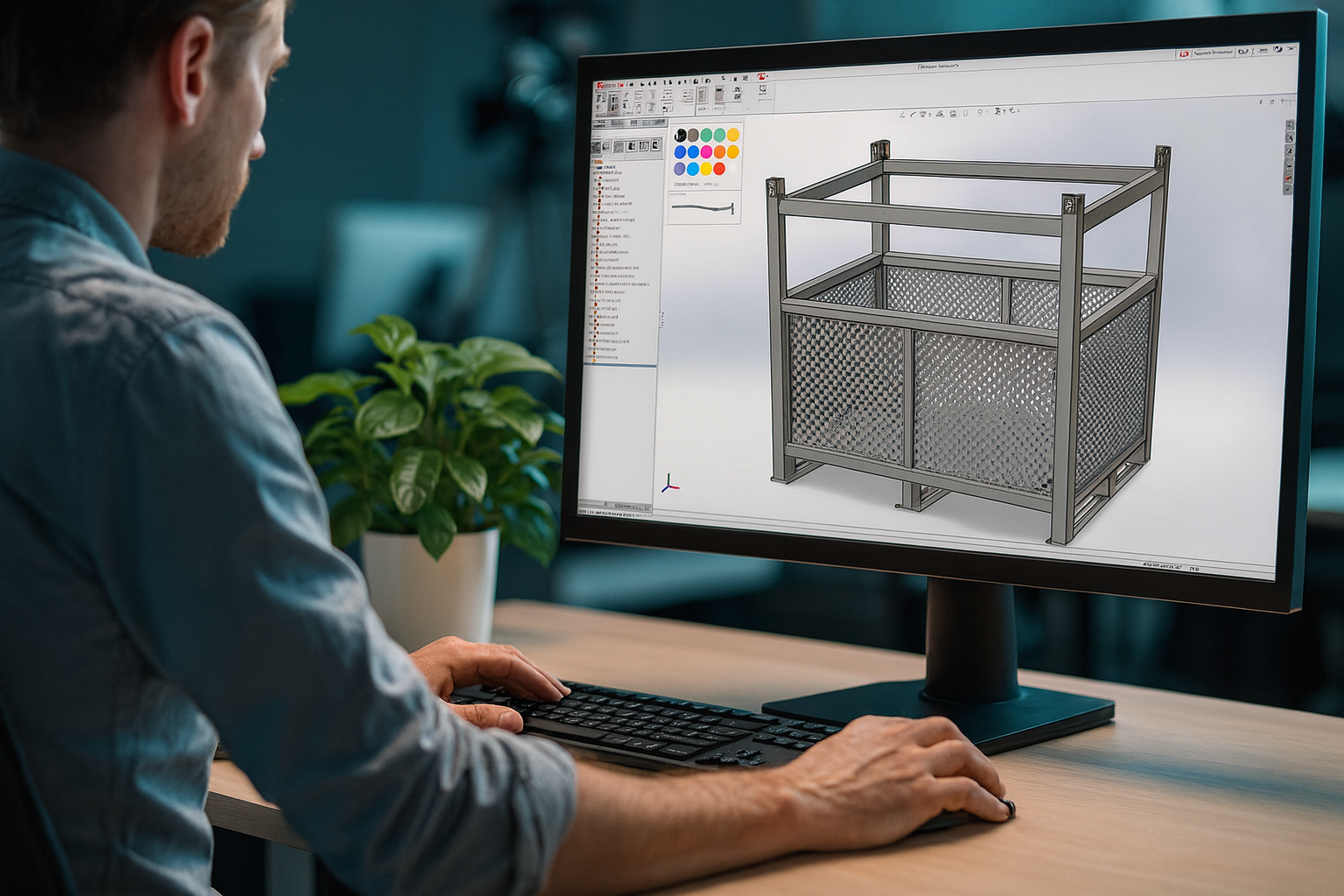

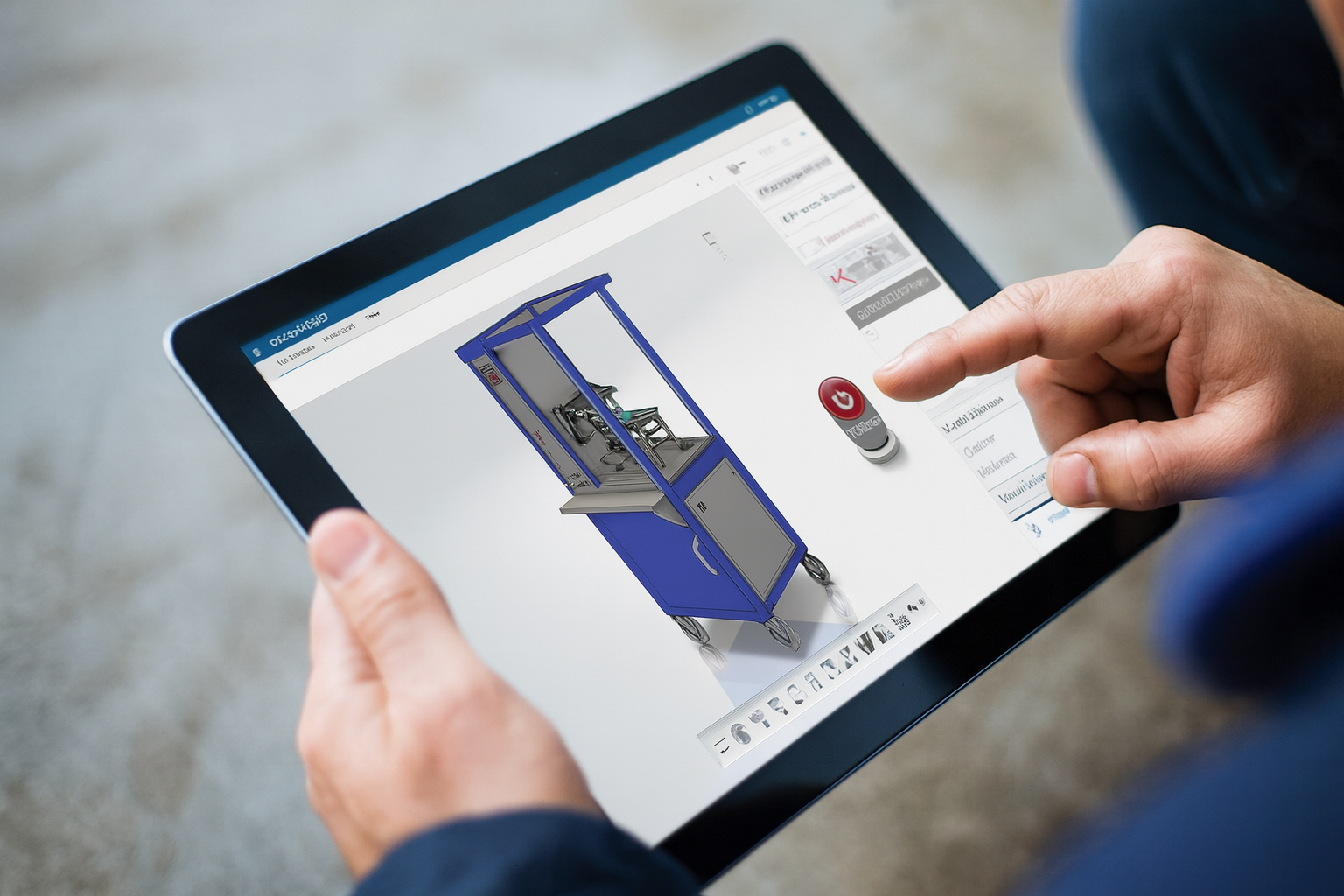

At Lowe Stillages and Cages, we use the latest SolidWorks 2025 3D CAD software to design bespoke storage solutions, such as custom stillages and cages tailored to your needs. Our clients typically provide technical requirements or share part files (like STEP/.stp or other CAD formats), and our experienced design team transforms these into a custom stillage solution that meets every specification. We pride ourselves on precision and collaboration – by involving you in the design process with concept visuals and feedback loops, we ensure the final product is exactly what your business requires.

Benefits of CAD & 3D Printing in Stillage Design

Our use of advanced CAD and 3D printing technology brings numerous benefits to the design and prototyping process. We work closely with you from the start, producing detailed concept drawings and 3D models that demonstrate exactly how your stillage will function. This upfront collaboration ensures every requirement is met and approved before manufacturing begins, preventing costly changes later on.

We also leverage in-house 3D printing capabilities to streamline development and improve the final product:

-

Rapid prototyping:

We can 3D print prototype dunnage (protective inserts) quickly and accurately, allowing us to test and refine designs without waiting for full production. -

Our team creates custom polyurethane dunnage moulds via 3D printing, which help reduce the overall weight of the stillage while maintaining strength and durability.

-

By iterating with 3D-printed samples, we can identify enhancements that improve the efficiency and durability of the final stillage design before committing to full-scale production.

Optimised Functionality and Flexibility

Using SolidWorks, our engineers build virtual 3D models to give you a complete proof of concept of your stillage design. These digital models show exactly how your stillage will accommodate a wide range of part sizes, weights, and shapes, ensuring the final product is versatile and fit for purpose. You can even virtually "load" your stillage with different components to verify that it meets all usage scenarios. This process gives you confidence that your custom stillage will perform as expected in real-world conditions and allows for adjustments early on if needed.

Efficient Space Utilisation

Our precise CAD designs enable us to tailor each stillage to your facility’s layout and storage requirements. We optimise dimensions and configurations so that every stillage makes the most of your available floor and warehouse space. Whether the stillages are in use or stacked when not needed, they will maximise storage capacity without compromising on accessibility or safety. This efficient space utilisation means you can handle more inventory or equipment within the same footprint, ultimately contributing to smoother workflows and cost savings.