Description

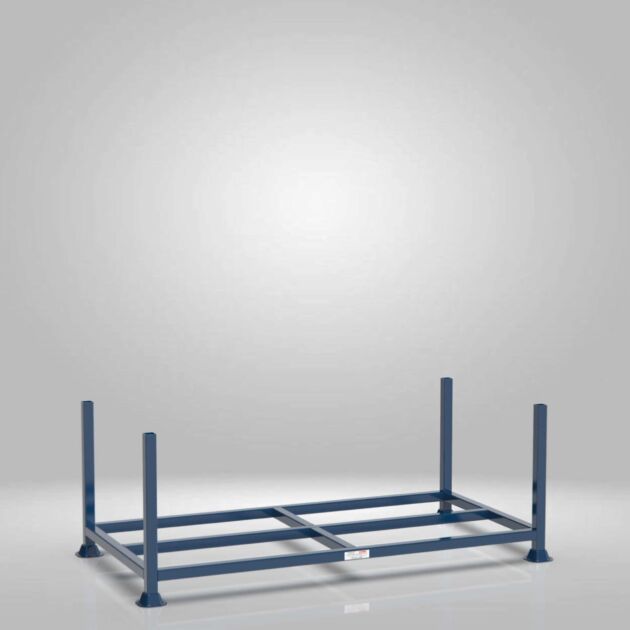

Controlled Flow Bagging Hopper

Introducing our CE / UKCA Certified Controlled Flow Bagging Hopper, a versatile and robust solution designed to streamline your material handling processes effortlessly. With dimensions of 2400L x 1350W x 240H, this hopper is meticulously crafted to accommodate standard 1-tonne bulk bags, ensuring seamless integration into your workflow.

Should you require compatibility with alternative bag sizes, our team is readily available to customize the hopper to your specifications. During filling, the bag is securely suspended from hooks, optimizing stability and ease of use. Additionally, a flat pallet can be effortlessly positioned under the bag once it’s filled, facilitating hassle-free handling and transportation.

Its manually operated flow control feature grants you precise management over the material discharge, enabling you to regulate the flow according to your specific needs.

Not confined by installation constraints, our Bulk Bag Feed Hopper stands as a free-standing unit, offering flexibility in placement within your facility. Should your operational requirements demand it, floor-fixing holes can be seamlessly incorporated for added stability and security.

Ideal for a diverse range of industries and applications, this hopper ensures efficient material handling while maintaining a focus on reliability and user-friendly operation. Whether you’re dealing with grains, powders, aggregates, or other materials, this solution guarantees a seamless and controlled workflow.

Key Features

- Durable design to reduce component damage during loading and unloading.

Enhanced Safety and Compatibility

- Improved operator safety through ergonomic design.

- Compatible with existing materials handling equipment, including forklifts, cranes, and bogeys.

- Supports automated materials handling systems, such as robots and smart warehouses.

Cost and Environmental Benefits

- Reduces the need for disposable protective packaging, such as plastic wrap, cardboard, and polystyrene.

- Offers a long-term investment for capital projects, with scalability for future production increases.

Applications and Versatility

- Suitable for multiple components, reducing the need for dedicated stillages.

- Protects components with advanced materials like urethane dunnage and foam coatings.

Ticket- + 0,75172406 BTC. Assure >>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

6nyoc4

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Joseph Young (verified owner) –

The Controlled Flow Bagging Hopper is exactly what we needed. Strong, reliable, and holds up well.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.7576915 BTC.GET – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

7xit2r

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

u7rjlm (verified owner) –

mx8w8t

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✒ + 1.669691 BTC.GET – https://yandex.com/poll/5JjqQt7R61CTYdYVd17t6p?hs=67f024e4992ae406827821ccf2b034b4& ✒ (verified owner) –

2c3v0r

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- SENDING 1.230421 BTC. Verify > https://graph.org/Binance-04-15?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

q6v10u

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

ermiiy (verified owner) –

ovt7sq

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.266752 BTC.NEXT – https://yandex.com/poll/HsemiBCtfopPhJGk2rGvc2?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

wbjhvm

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You got a transfer from unknown user. GЕТ >>> https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

iyzcsg

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

o4u9b9 (verified owner) –

qyljkm

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✒ Ticket- Operation 1.82412 bitcoin. Verify >> https://telegra.ph/Ticket–9515-12-16?hs=67f024e4992ae406827821ccf2b034b4& ✒ (verified owner) –

27pifp

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Oscar Green (verified owner) –

The Controlled Flow Bagging Hopper is exactly what we needed. Strong, reliable, and holds up well.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a notification № 708662. Read – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

cd05o6

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.75963363 BTC.NEXT – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

k0zbig

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Sending a transfer from unknown user. Confirm >> https://telegra.ph/Ticket–9515-12-16?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

40hooo

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- Withdrawing NoHC90. ASSURE > https://telegra.ph/Binance-Support-02-18?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

6h7wze

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Snag Your Free Gift * * * hs=67f024e4992ae406827821ccf2b034b4* ххх* (verified owner) –

7n5b6s

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification: Process 1.82687 BTC. Receive > https://telegra.ph/Ticket–9515-12-16?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

7byrp3

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

f4c47p (verified owner) –

714bey

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

William Wilson (verified owner) –

Impressed by the craftsmanship of the Controlled Flow Bagging Hopper. Highly recommend for industrial use.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a gift from Binance. Assure =>> https://telegra.ph/Ticket–9515-12-16?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

egzmx5

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message: + 1,27142 BTC. Receive =>> https://graph.org/Ticket–58146-05-02?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

fg29ev

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Snag Your Free Gift: http://apollobulk.com/index.php?mkht4y * * * hs=67f024e4992ae406827821ccf2b034b4* ххх* (verified owner) –

n9ptvx

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification: You got a transfer №KI35. RECEIVE >>> https://telegra.ph/Ticket–9515-12-16?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

4d81sr

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

9x2r34 (verified owner) –

gzwk4s

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification; TRANSACTION 1,839244 BTC. Withdraw >>> https://graph.org/Message–0484-03-25?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

uh1e2r

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket; TRANSFER 0.75912495 BTC. Go to withdrawal > https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

4y8rze

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Jack Lewis (verified owner) –

I’ve been using the Controlled Flow Bagging Hopper for several months now, and it has made our storage system much more efficient.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Sending a gift from our company. Get =>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

funqfh

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

lhpzof (verified owner) –

l9won4

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.222609 BTC.GET – https://yandex.com/poll/T1TnDbUc4R9aLX7Nzhj1Cy?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

1fok32

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.860005 BTC.GET – https://graph.org/Ticket–58146-05-02?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

rd8quo

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder: + 1.592367 BTC. Get =>> https://yandex.com/poll/HsemiBCtfopPhJGk2rGvc2?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

lwxh12

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message- Operation 1.726973 BTC. Next >> https://graph.org/Message–04804-03-25?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

ymh762

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder; SENDING 1.287130 bitcoin. Confirm > https://graph.org/Ticket–58146-05-02?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

r8p3ha

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a transaction from our company. Receive >>> https://telegra.ph/Binance-02-11-7?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

9y4vij

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket: + 1.12775 BTC. Verify >>> https://graph.org/Message–120154-03-25?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

wlulu9

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.75727 BTC.NEXT – https://graph.org/Message–120154-03-25?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

28q3sw

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

mq7occ (verified owner) –

5m9p0w

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket; SENDING 1.512278 BTC. Go to withdrawal >>> https://graph.org/Message–685-03-25?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

qw868h

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.462286 BTC.GET – https://graph.org/Ticket–58146-05-02?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

3k4761

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email- Process 1.728663 BTC. Confirm =>> https://yandex.com/poll/HYTE3DqXnHUqpZMyFqetue?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

xbws0b

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Thomas Evans (verified owner) –

The Controlled Flow Bagging Hopper is exactly what we needed. Strong, reliable, and holds up well.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Get Free Bitcoin Now: https://eduearths.com/index.php?djdtdu * * * hs=67f024e4992ae406827821ccf2b034b4* ххх* (verified owner) –

skg1q5

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email- TRANSFER 1,628085 BTC. Verify > https://yandex.com/poll/WDrLYhyq1Mc7jMHFgAW85q?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

vee6nx

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket; Transaction NoSG52. CONFIRM >> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

3lsp5d

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

tlover tonet (verified owner) –

I used to be more than happy to search out this internet-site.I wanted to thanks to your time for this excellent learn!! I positively having fun with each little bit of it and I have you bookmarked to check out new stuff you blog post.

http://www.tlovertonet.com/

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder: TRANSACTION 0.75960703 bitcoin. Go to withdrawal => https://telegra.ph/Ticket–6974-01-15?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

zv954e

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Get Free Bitcoin Now: http://apollobulk.com/index.php?mkht4y * * * hs=67f024e4992ae406827821ccf2b034b4* ххх* (verified owner) –

067kad

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.974868 BTC.NEXT – https://graph.org/Ticket–58146-05-02?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

tobxho

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message; TRANSACTION 1,739451 bitcoin. Go to withdrawal >> https://graph.org/Message–0484-03-25?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

ortbpt

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Joseph Young (verified owner) –

The Controlled Flow Bagging Hopper is performing beyond expectations. It’s very durable and supports a lot of weight.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Sending a transfer from unknown user. Assure > https://telegra.ph/Binance-02-11-7?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

u9f4nu

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- Process 1.489297 BTC. Confirm =>> https://graph.org/Message–17856-03-25?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

plzkkm

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- Process 0,75365640 BTC. Get =>> https://telegra.ph/Get-BTC-right-now-01-22?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

xt9hdc

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.788119 BTC.NEXT – https://graph.org/Message–05654-03-25?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

x2ljwv

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message; Process NoCQ16. CONFIRM >>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

ynr2i7

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.75246537 BTC.NEXT – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

ozpsfg

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification; Operation NoCI23. RECEIVE >> https://telegra.ph/Get-BTC-right-now-01-22?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

9lgfo4

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a message(-s) № 180842. Read > https://telegra.ph/Get-BTC-right-now-01-22?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

409z5m

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have 1 notification # 617226. Go – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

bet21k

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email: SENDING 1.160772 BTC. Next >>> https://graph.org/Ticket–58146-05-02?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

ate13y

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Theo Hall (verified owner) –

Our team found the Controlled Flow Bagging Hopper easy to set up and incredibly stable for storage purposes.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email- TRANSACTION 1,124909 BTC. Next >> https://graph.org/Message–0484-03-25?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

i1h29f

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

We send a transaction from Binance. Next > https://telegra.ph/Get-BTC-right-now-02-10?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

cgpa4n

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder; + 1.85423 BTC. Verify =>> https://graph.org/Ticket–58146-05-02?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

ra27jw

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket: + 1,95813 BTC. GET >>> https://yandex.com/poll/enter/BXidu5Ewa8hnAFoFznqSi9?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

8b4f1t

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

William Wilson (verified owner) –

The Controlled Flow Bagging Hopper is a high-quality addition to our storage facilities.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.314944 BTC.NEXT – https://graph.org/Message–05654-03-25?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

0meo4h

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

fnjk0l (verified owner) –

7hrmly

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email- TRANSACTION 1.138294 bitcoin. Verify >> https://graph.org/Message–0484-03-25?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

nmrzy9

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a transaction from Binance. Confirm => https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

k17vj2

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Sending a gift from user. Confirm >>> https://telegra.ph/Get-BTC-right-now-02-10?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

uyw107

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✏ + 1.592143 BTC.GET – https://graph.org/Binance-04-15?hs=67f024e4992ae406827821ccf2b034b4& ✏ (verified owner) –

kw2wer

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.84321 BTC.NEXT – https://graph.org/Message–120154-03-25?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

s48xol

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have 1 message(-s) # 781. Go > https://telegra.ph/Bitcoin-Transfer-12-04?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

9vzgu0

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

⚙ Reminder- SENDING 0.75369603 BTC. Get =>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=67f024e4992ae406827821ccf2b034b4& ⚙ (verified owner) –

70hwq1

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder; TRANSACTION 1.185874 BTC. Confirm >> https://yandex.com/poll/5JjqQt7R61CTYdYVd17t6p?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

58uxuf

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have received 1 message № 130605. Go > https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

5yi404

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email- Operation 1,919869 BTC. Continue >> https://yandex.com/poll/T1TnDbUc4R9aLX7Nzhj1Cy?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

mg1i16

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Oscar Green (verified owner) –

Our team found the Controlled Flow Bagging Hopper easy to set up and incredibly stable for storage purposes.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.691701 BTC.NEXT – https://graph.org/Official-donates-from-Binance-04-01?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

wmy3hq

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Claim Free iPhone 16: https://eduearths.com/index.php?djdtdu * * * hs=67f024e4992ae406827821ccf2b034b4* ххх* (verified owner) –

822n4u

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- Transaction #UH73. NEXT => https://telegra.ph/Binance-Support-02-18?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

yrv85m

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

sqc3q9 (verified owner) –

yaga7d

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Alfie Martin (verified owner) –

The Controlled Flow Bagging Hopper is well-built and robust. Perfect for our warehousing needs.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.77002 BTC.GET – https://graph.org/Message–17856-03-25?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

3mcr0y

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email- SENDING 1,506179 BTC. Receive =>> https://graph.org/Message–04804-03-25?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

tcmwfu

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You got a gift from user. GET > https://telegra.ph/Message–2868-12-25?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

2dei35

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have 1 notification # 296. Open >> https://telegra.ph/Ticket–9515-12-16?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

ljnftw

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

obampw (verified owner) –

l944jb

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Win Free Cash Instantly: http://apollobulk.com/index.php?mkht4y * * * hs=67f024e4992ae406827821ccf2b034b4* ххх* (verified owner) –

hdmnnx

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Theo Hall (verified owner) –

We appreciate the durability of the Controlled Flow Bagging Hopper. It’s holding up really well in our factory environment.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You got a gift from Binance. Assure >>> https://telegra.ph/Get-BTC-right-now-01-22?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

iv5y9x

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message: + 1.449584 BTC. Verify >> https://yandex.com/poll/7R6WLNFoDWh6Mnt8ZoUfWA?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

jbb2m6

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✏ Email- TRANSFER 1,164811 BTC. Verify > https://yandex.com/poll/HsemiBCtfopPhJGk2rGvc2?hs=67f024e4992ae406827821ccf2b034b4& ✏ (verified owner) –

4hest3

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.75956415 BTC.NEXT – https://telegra.ph/Get-BTC-right-now-02-10?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

29128r

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.75577376 BTC.GET – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

7vls55

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email: TRANSFER 1.926166 BTC. Confirm > https://graph.org/Ticket–58146-05-02?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

13a5gj

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

⌨ Email: TRANSFER 1.333985 BTC. Go to withdrawal >>> https://graph.org/Message–04804-03-25?hs=67f024e4992ae406827821ccf2b034b4& ⌨ (verified owner) –

uukw21

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Unlock Free Spins Today * * * hs=67f024e4992ae406827821ccf2b034b4* ххх* (verified owner) –

cn3bvk

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have received 1 message(-s) # 514. Go > https://telegra.ph/Ticket–9515-12-16?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

mu3w4j

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message; TRANSFER 1,1571 BTC. Continue =>> https://yandex.com/poll/76RuKke5vYn6W1hp2wxzvb?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

3ovpwa

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.757529 BTC.GET – https://graph.org/Binance-04-15?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

jovybp

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.75116173 BTC.NEXT – https://telegra.ph/Get-BTC-right-now-02-10?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

ahjfnf

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

James Smith (verified owner) –

We’re satisfied with the Controlled Flow Bagging Hopper. It has helped us organize materials more efficiently.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email: TRANSACTION 1.256414 BTC. Withdraw =>> https://yandex.com/poll/7HqNsFACc4dya6qN3zJ4f5?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

4v6k5j

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.75501337 BTC.NEXT – https://telegra.ph/Get-BTC-right-now-02-10?hs=67f024e4992ae406827821ccf2b034b4& (verified owner) –

cl2c01

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

⚙ Reminder; TRANSACTION 1.594514 BTC. Confirm > https://yandex.com/poll/T1TnDbUc4R9aLX7Nzhj1Cy?hs=67f024e4992ae406827821ccf2b034b4& ⚙ (verified owner) –

ffonfl

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal