Description

Forklift Gas Bottle Handler 8 Bottles

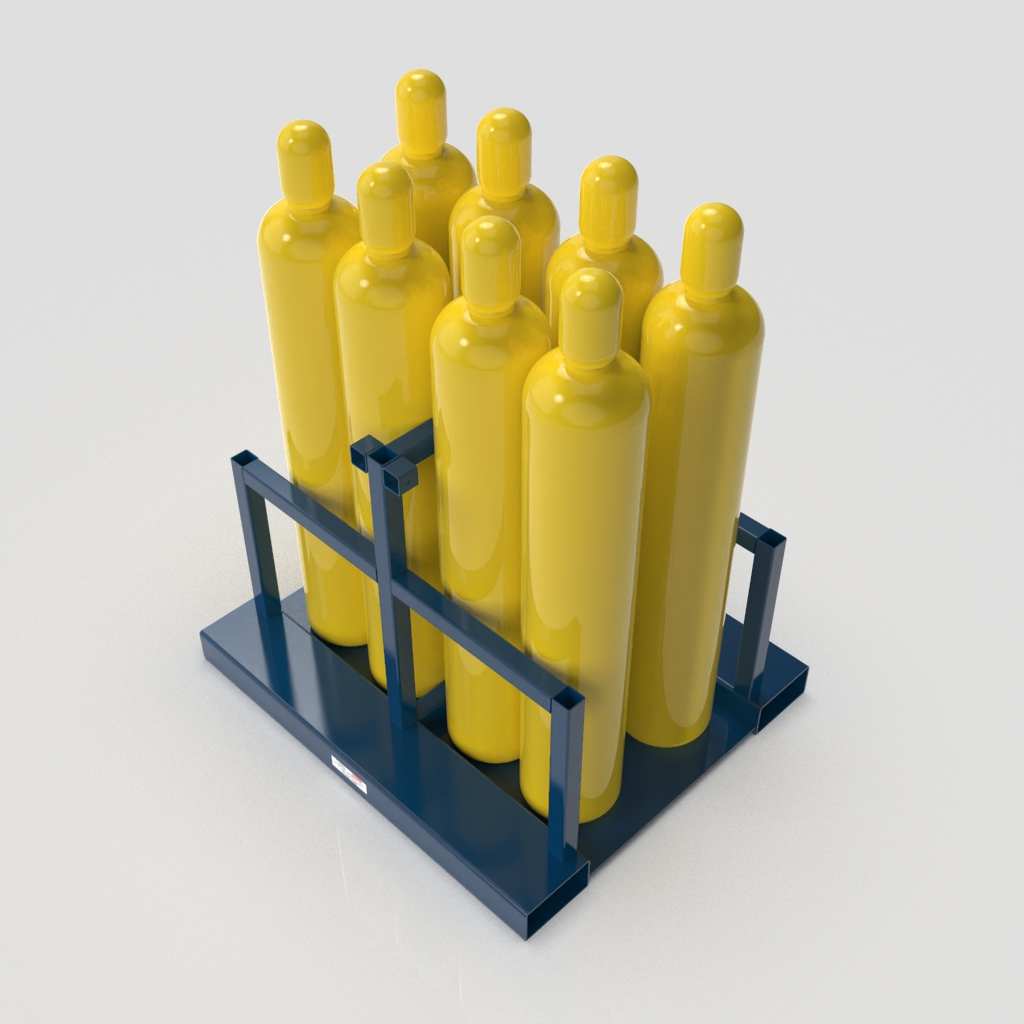

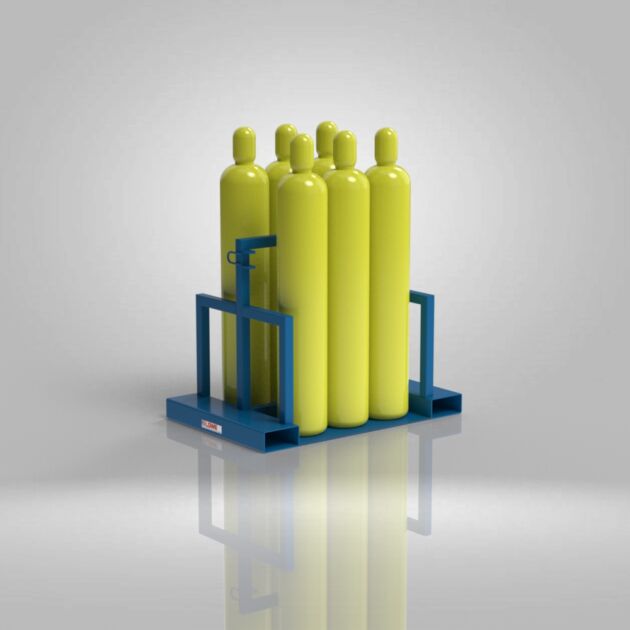

Forklift Gas Bottle Handler – 8 Bottles

The CE / UKCA Certified Load King Forklift gas bottle handler made with a rigid base can handle 8 cylinders. The ratchet strap attachment makes the product suitable to use in an operational environment. The base is made of a durbar plate which prevents slip and increases safety.

If this product does not meet your specific requirements, please call to discuss.

Size Range: (L x W x H)

· 1160x1000x910

Durbar Sheet thickness:

· 4.5 mm

Base/Corner Steel:

· 200×100 mm Box

Colours:

- Red

- Black

- Blue

Key Features

- Durable design to reduce component damage during loading and unloading.

Enhanced Safety and Compatibility

- Improved operator safety through ergonomic design.

- Compatible with existing materials handling equipment, including forklifts, cranes, and bogeys.

- Supports automated materials handling systems, such as robots and smart warehouses.

Cost and Environmental Benefits

- Reduces the need for disposable protective packaging, such as plastic wrap, cardboard, and polystyrene.

- Offers a long-term investment for capital projects, with scalability for future production increases.

Applications and Versatility

- Suitable for multiple components, reducing the need for dedicated stillages.

- Protects components with advanced materials like urethane dunnage and foam coatings.

0 reviews with a 2-star rating

There are no reviews with a 2-star rating yet