Description

Forklift Safety Access Cage

The CE / UKCA Certified Forklift Safety Access Cage provides an ideal solution for accessing operations at heightened hard to access places safely. The product has the capacity to hold two persons at a time using a forklift.

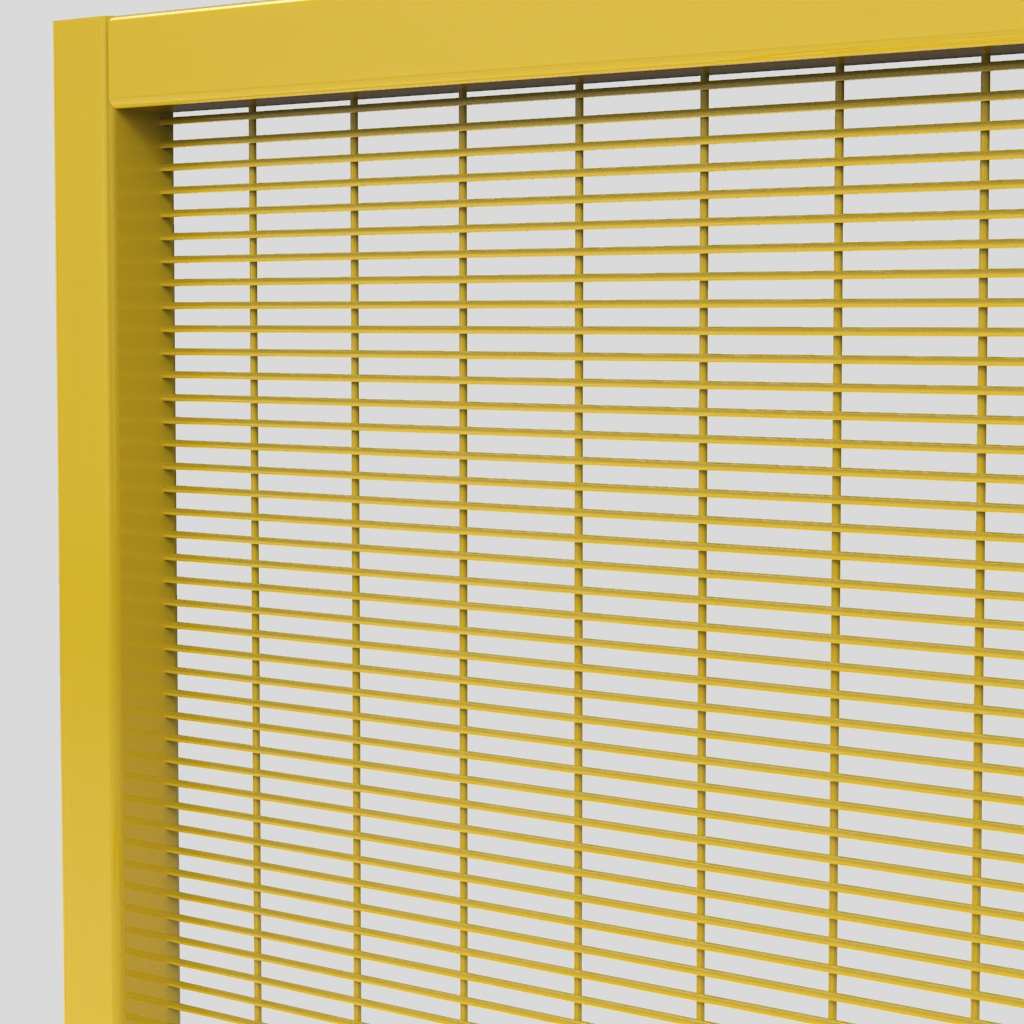

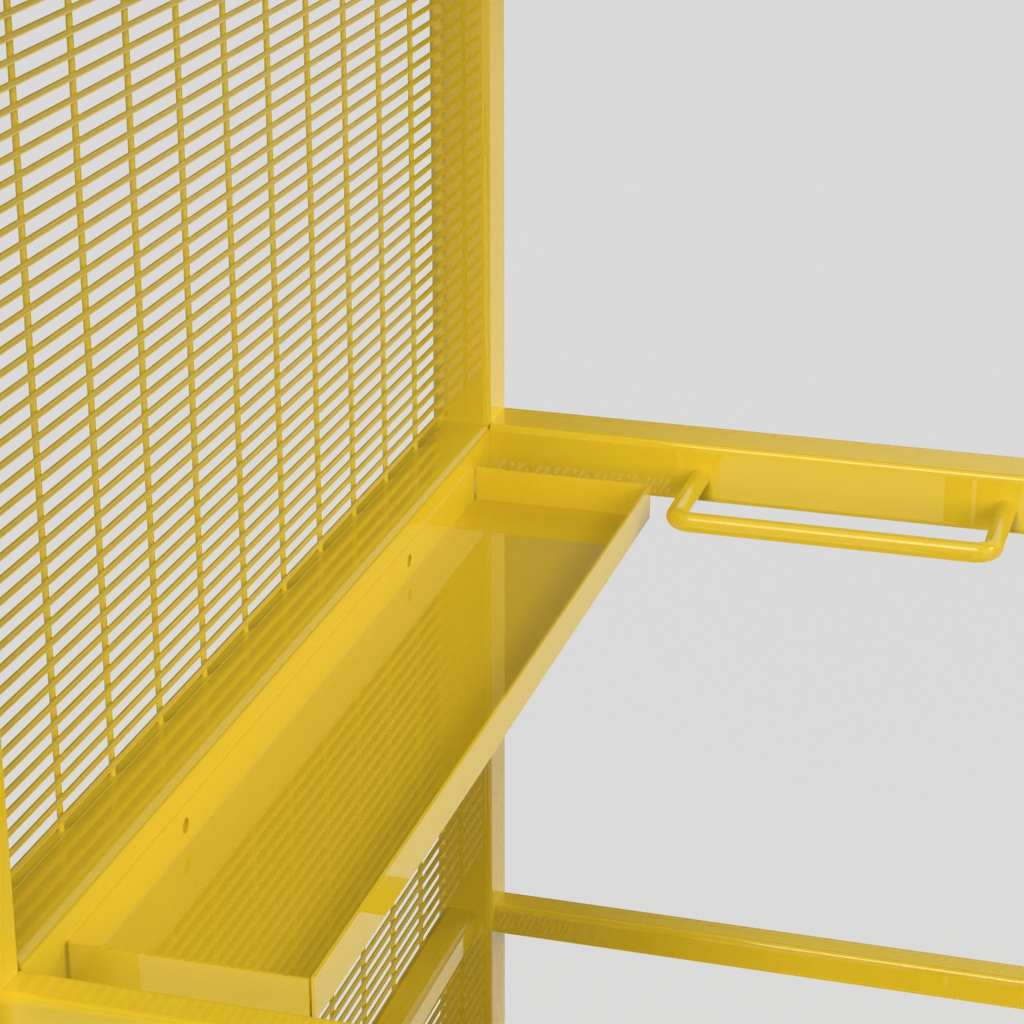

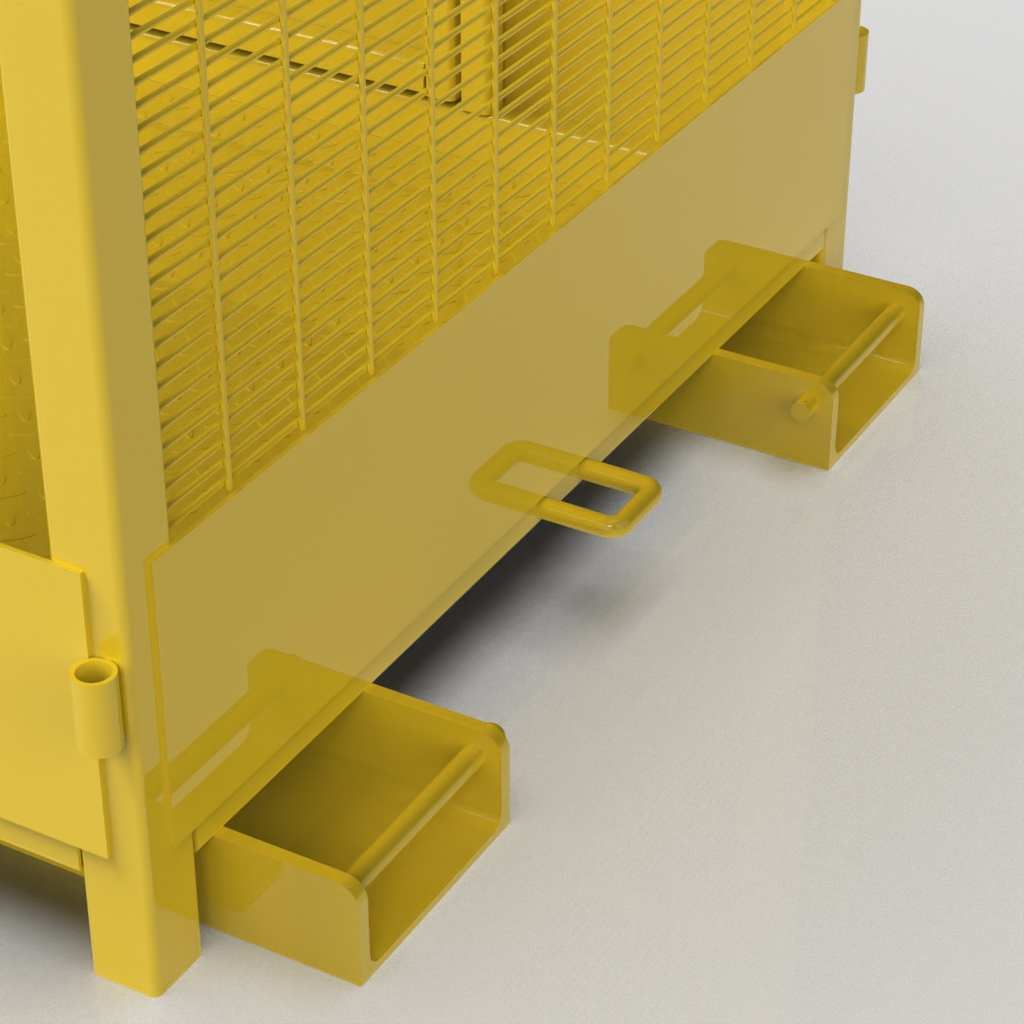

The platform is made up of anti-slip Durbar sheets to provide grip while standing on the cage. The base ensures that the persons are safe while being lifted or transported. The fork guides are having enough space for any forklift widths and can be locked before lifting to ensure steady movement. The side door can be opened and locked from inside. The back side of the cage is fitted with finger safe mesh to prevent any outside interference while handling the tools. Its mild steel construction provides a rigid and robust platform to hold almost anything and ensuring the security of the personnel on it. The base deck is made up of 4.5mm Durbar sheet which can bear the maximum load of the goods.

The stillage is suited for almost any industrial premises like Construction, Warehouse logistics, Retail, Factory outlets etc. It is highly advised that prior to lifting, the load of the stillage should be measured and not exceed 75 percent of the rated capacity (critical lift) of the lifting truck.

The Safety Access Cage are available in a range of hazard prevention colours.

For more information on the product, please visit our Gallery page.

Key Features

- Durable design to reduce component damage during loading and unloading.

Enhanced Safety and Compatibility

- Improved operator safety through ergonomic design.

- Compatible with existing materials handling equipment, including forklifts, cranes, and bogeys.

- Supports automated materials handling systems, such as robots and smart warehouses.

Cost and Environmental Benefits

- Reduces the need for disposable protective packaging, such as plastic wrap, cardboard, and polystyrene.

- Offers a long-term investment for capital projects, with scalability for future production increases.

Applications and Versatility

- Suitable for multiple components, reducing the need for dedicated stillages.

- Protects components with advanced materials like urethane dunnage and foam coatings.

0 reviews with a 1-star rating

There are no reviews with a 1-star rating yet