Polyurethane Dunnage for Custom Stillages

At Lowe Stillages & Cages we engineer more than just steel. Our polyurethane dunnage solutions are built to protect your valuable components with pinpoint precision. Whether you're transporting automotive parts, aerospace assemblies or high-value industrial goods, our custom-moulded dunnage ensures everything arrives in perfect condition again and again.

What Is Polyurethane Dunnage?

Polyurethane (PU) is a highly adaptable polymer, valued for its strength, resilience, and shock absorbing properties. By casting PU into custom moulds, we create protective packaging inserts that fit your components exactly, locking them securely in place during handling, transport or storage.

At Lowe we design and manufacture bespoke polyurethane dunnage specifically for use in our stillages and cages. Each insert is engineered to deliver durability, safety and space efficiency, helping you reduce waste, avoid damage and improve operational flow.

Shock Absorption

PU foam absorbs impacts and reduces vibration, protecting parts during transit.

Reusability & Durability

Unlike single use materials, our dunnage is built for long term industrial use.

Environmental Resistance

Performs reliably in heat, cold, moisture and exposure to oils or chemicals.

Sustainability

Reduces packaging waste and supports greener operational practices.

Cost Efficiency

Prevents damage, reduces packaging waste and lowers replacement spend.

Why Choose Lowe's Custom PU Dunnage?

We don’t believe in one size fits all. That’s why every dunnage project at Lowe starts with a conversation, about your parts, your challenges, and your handling environment. Then, our in-house design and production team gets to work, using SolidWorks 3D CAD and 3D-printed tooling to create the ideal PU insert for your stillage system.

Our polyurethane dunnage is designed to:

- Secure your components safely in place – no movement, no damage

- Absorb shock and vibration during transit or forklift handling

- Protect finishes on delicate or precision-engineered parts

- Streamline loading/unloading, with clearly defined part positions

- Last through repeated use, lowering costs over time

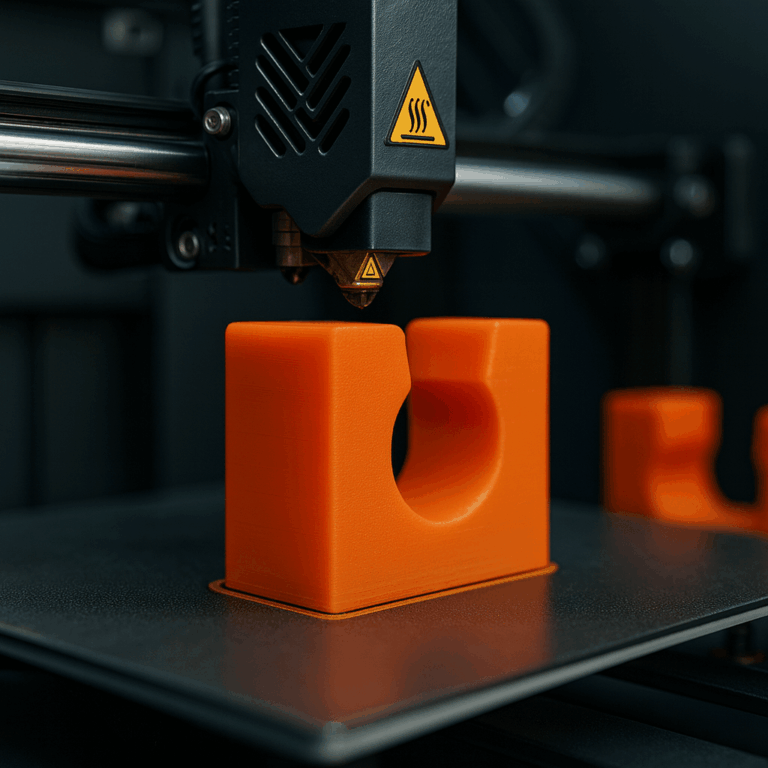

The Lowe Advantage: 3D-Printed Tooling for Perfect Fit

We use 3D printing to produce the tooling for all our PU moulds. This means:

- Faster turnaround from concept to production

- Higher accuracy for complex or unusual geometries

- Reduced prototyping costs

- Perfect fit — first time, every time

Whether you're storing hundreds of identical parts or handling one-off fabrications, Lowe's polyurethane dunnage ensures the right fit and lasting protection.

Built to Protect. Designed to Fit. Backed by Lowe.

If you’re investing in custom stillages, don’t stop at the steel. Lowe’s polyurethane dunnage inserts add the precision and protection your products deserve all engineered in house by our specialist team.

Ready to start your next project? Contact our design team to discuss your requirements, or explore our CAD & 3D printing services to learn how we bring your dunnage to life.