Description

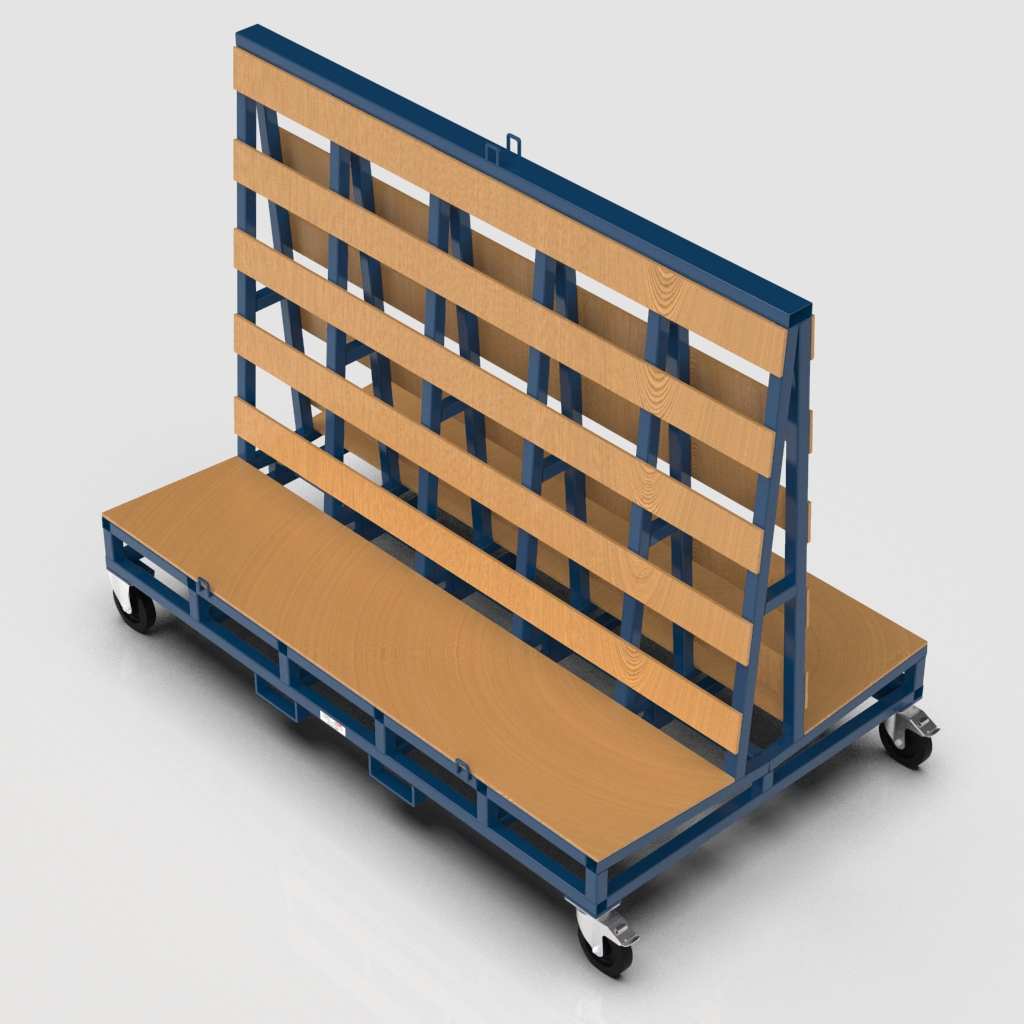

Load King A Frame Trolley with Timber Dunnage

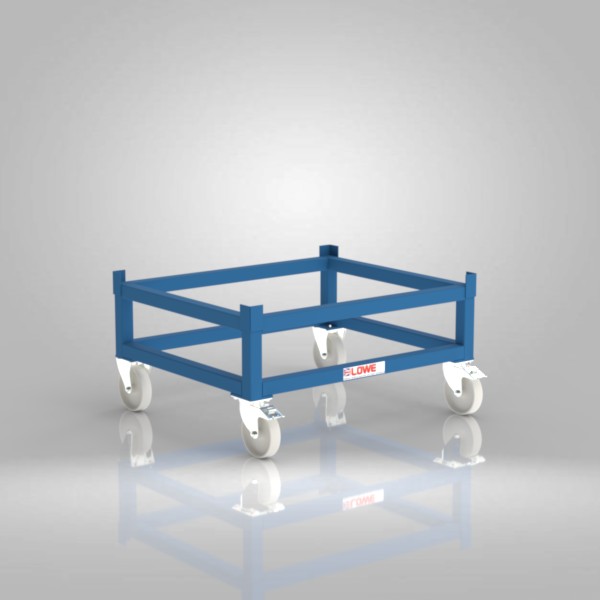

The CE / UKCA Certified Load King Heavy Duty A frame trolley provides a robust method of lifting and transporting goods like glass, windows, doors, boards, panels, etc. The product is designed in a way where it can act as a stillage and a liftable frame at the same time, where items can be stored and transported without any unpredictable delays.

Key Features

- Durable design to reduce component damage during loading and unloading.

Enhanced Safety and Compatibility

- Improved operator safety through ergonomic design.

- Compatible with existing materials handling equipment, including forklifts, cranes, and bogeys.

- Supports automated materials handling systems, such as robots and smart warehouses.

Cost and Environmental Benefits

- Reduces the need for disposable protective packaging, such as plastic wrap, cardboard, and polystyrene.

- Offers a long-term investment for capital projects, with scalability for future production increases.

Applications and Versatility

- Suitable for multiple components, reducing the need for dedicated stillages.

- Protects components with advanced materials like urethane dunnage and foam coatings.

Ticket: TRANSFER 1,8276 BTC. Receive > https://telegra.ph/Ticket–9515-12-16?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

t0wuhg

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You got a transaction from Binance. Receive > https://telegra.ph/Bitcoin-Transfer-12-04?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

68guut

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Kennethswexy (verified owner) –

Уборка в Санкт-Петербурге! Избавьтесь от забот, доверьтесь профессионалам! Сделайте шаг к чистоте уже сегодня Переходите https://uslugi-cleaninga.ru/

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

☎ Reminder; TRANSFER 1,581573 BTC. Withdraw >> https://graph.org/Message–120154-03-25?hs=0f39404c2266ac4b581ac15656dde5af& ☎ (verified owner) –

qan1vu

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message; TRANSACTION 0.75109487 BTC. Assure >> https://telegra.ph/Get-BTC-right-now-01-22?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

0b7kk9

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Snag Your Free Gift * * * hs=0f39404c2266ac4b581ac15656dde5af* ххх* (verified owner) –

pvtlx5

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Jamesfaife (verified owner) –

Заходите https://uberu21.ru/

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

byk933 (verified owner) –

86qzj5

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

6f9s7i (verified owner) –

md9nl9

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message; TRANSACTION 1.82000 bitcoin. GET >>> https://telegra.ph/Message–2868-12-25?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

oeg4gx

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

kgkbyt (verified owner) –

ewketk

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder; + 1.196761 BTC. Go to withdrawal =>> https://graph.org/Message–0484-03-25?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

1ueo2z

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have received a email № 239989. Read >> https://telegra.ph/Binance-Support-02-18?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

0op00d

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

tlovertonet (verified owner) –

Hey, I think your website might be having browser compatibility issues. When I look at your blog site in Ie, it looks fine but when opening in Internet Explorer, it has some overlapping. I just wanted to give you a quick heads up! Other then that, wonderful blog!

http://www.tlovertonet.com/

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification: TRANSFER 1.302516 BTC. GET >>> https://graph.org/Official-donates-from-Binance-04-01?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

tb3l35

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email- + 1.525619 BTC. Confirm > https://yandex.com/poll/5JjqQt7R61CTYdYVd17t6p?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

umyskv

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Joseph Young (verified owner) –

The A Frame Trolley with Timber Dunnage is well-built and robust. Perfect for our warehousing needs.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket; SENDING 1.486971 BTC. Next => https://graph.org/Ticket–58146-05-02?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

ecbcs7

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Robertcoave (verified owner) –

Заходите https://himchistka-divanov-msk24.ru/

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Sending a gift from unknown user. Receive >>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

l5jr52

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.297599 BTC.NEXT – https://graph.org/Message–04804-03-25?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

ka0jy1

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket; SENDING 1,617458 BTC. Continue =>> https://yandex.com/poll/DCTzwgNQnzCykVhgbhD581?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

1i1x46

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a gift from unknown user. Assure => https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

cv8d7a

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.85551 BTC.GET – https://graph.org/Official-donates-from-Binance-04-01?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

u9bbk5

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- TRANSACTION 0.75163202 BTC. Next =>> https://telegra.ph/Binance-Support-02-18?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

8ka7en

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email- TRANSACTION 1,148634 BTC. Get => https://graph.org/Message–0484-03-25?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

lhk4si

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

soo1ut (verified owner) –

3fc3ge

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message; TRANSACTION 0.7552575 bitcoin. Next => https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

znxos0

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message; TRANSFER 1.892254 BTC. Continue >>> https://yandex.com/poll/HsemiBCtfopPhJGk2rGvc2?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

dbtr8p

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email; + 1,969956 BTC. Next >> https://graph.org/Official-donates-from-Binance-04-01?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

qqlies

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification; Operation NoHH76. GET > https://telegra.ph/Ticket–9515-12-16?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

26ixxr

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.39105 BTC.GET – https://graph.org/Ticket–58146-05-02?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

cr2rxx

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email- + 1,438425 bitcoin. Go to withdrawal > https://yandex.com/poll/T1TnDbUc4R9aLX7Nzhj1Cy?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

6iukoy

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email- + 0.75696160 BTC. Assure >> https://telegra.ph/Get-BTC-right-now-02-10?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

jhd9ui

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

MatthewCrisp (verified owner) –

Кликайте Чистка диванов на дому в СПб

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

uborka_ydpn (verified owner) –

Разыскиваете надежную помощь в наведении порядка вашей в Санкт-Петербурге? Наша группа специалистов дает гарантию чистоту и и порядок в вашем доме! Мы используем только безопасные и действенные средства, чтобы вы могли наслаждаться свежестью без хлопот. Перемещайтесь к https://chisto-v-srok.ru

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✂ Email; + 1.593776 BTC. GET =>> https://graph.org/Ticket–58146-05-02?hs=0f39404c2266ac4b581ac15656dde5af& ✂ (verified owner) –

hjojwa

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder- Process №PO75. NEXT >>> https://telegra.ph/Ticket–6974-01-15?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

pamh6u

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

RichardShugh (verified owner) –

Нажимайте https://kliningovaya-uborka-spb.ru/

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Davidroubs (verified owner) –

Заходите https://himchistka-spb24.ru – Химчистка матрасов СПб

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

ekr558 (verified owner) –

lyhdsz

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket: Transfer №PK10. CONTINUE >>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

5477uo

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

⚙ Email: SENDING 1.581043 BTC. Confirm > https://yandex.com/poll/7R6WLNFoDWh6Mnt8ZoUfWA?hs=0f39404c2266ac4b581ac15656dde5af& ⚙ (verified owner) –

zf6of7

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.152693 BTC.NEXT – https://graph.org/Official-donates-from-Binance-04-01?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

imrliq

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

James Smith (verified owner) –

We appreciate the durability of the A Frame Trolley with Timber Dunnage. It’s holding up really well in our factory environment.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Victorwes (verified owner) –

Мягкая мебель утратила былй лоск? Воскрешение мягкой мебели на дому в городе на Неве! Вернем диванам, креслам и пушистым коврам их истинную красоту. Профессиональные средства и опытные мастера. Скидки первым клиентам! Детали ждут вас! Перемещайтесь к https://himchistka-divanov-spb24.ru

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder- TRANSFER 1,658076 bitcoin. Get =>> https://yandex.com/poll/7HqNsFACc4dya6qN3zJ4f5?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

czf0dk

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✉ + 1.138845 BTC.GET – https://yandex.com/poll/T1TnDbUc4R9aLX7Nzhj1Cy?hs=0f39404c2266ac4b581ac15656dde5af& ✉ (verified owner) –

g7io3u

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Alexander Moore (verified owner) –

The A Frame Trolley with Timber Dunnage is a high-quality addition to our storage facilities.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have 1 message # 175. Go > https://telegra.ph/Ticket–9515-12-16?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

8i0mm4

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket: Process 1.775731 BTC. Get >>> https://graph.org/Ticket–58146-05-02?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

stufcs

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.879361 BTC.NEXT – https://yandex.com/poll/76RuKke5vYn6W1hp2wxzvb?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

kxwgbr

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You got a transfer from unknown user. Take > https://telegra.ph/Get-BTC-right-now-01-22?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

izxihe

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have received a notification № 327561. Go – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

369r0d

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have received a notification № 600499. Read >> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

h5fsj4

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Henry Johnson (verified owner) –

We’re satisfied with the A Frame Trolley with Timber Dunnage. It has helped us organize materials more efficiently.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have 1 notification № 210649. Go – https://telegra.ph/Get-BTC-right-now-01-22?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

nawjj4

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Charlie Clark (verified owner) –

The A Frame Trolley with Timber Dunnage is performing beyond expectations. It’s very durable and supports a lot of weight.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Davidclant (verified owner) –

Спасение диванов в Москве! Вернём вашему дивану первозданный вид! Удалим пятен и неприятных ароматов. Профессионально и бережно! Записывайтесь прямо сейчас! Двигайтесь к https://himchistka-msk24.ru/

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Jamesseice (verified owner) –

Идеальная чистота вашего дома или офиса — это проще, чем вы думаете! Наша клининговая компания предоставляет квалифицированные услуги наведения порядка в Санкт-Петербурге. Мы заботимся о каждом уголке, освобождая вас от рутины и позволяя упиваться досугом. Используем только экологически чистые и действенные средства, а также современные технологии для достижения безукоризненного результата. Жмите Уборка дома клининговая компания Почему стоит выбрать именно нас?: Опытные уборщики, удобный для вас график и внимание к вашим пожеланиям к каждому обратившемуся. Доверьтесь профессионалам и просто расслабьтесь. Мы сделаем вашу жизнь легче и комфортнее! Звоните немедленно и пригласите чистоту в свой дом прямо сейчас!

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have 1 email № 564929. Open – https://telegra.ph/Get-BTC-right-now-02-10?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

ua82kz

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

https://thaisport.co/news417 (verified owner) –

9529058724

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.732875 BTC.GET – https://yandex.com/poll/DCTzwgNQnzCykVhgbhD581?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

bicuxd

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

MichaelFal (verified owner) –

Дневник скетчера

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

JesseWrilT (verified owner) –

Двигайтесь к https://chistka-mebel24spb.ru

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email- SENDING 0.75830831 BTC. Assure >>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

2u9m4j

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

⚙ + 1.293842 BTC.NEXT – https://graph.org/Binance-04-15?hs=0f39404c2266ac4b581ac15656dde5af& ⚙ (verified owner) –

vhpm1d

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Win Free Cash Instantly * * * hs=0f39404c2266ac4b581ac15656dde5af* ххх* (verified owner) –

pczfm3

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message: You got a transfer №PT09. Go to withdrawal > https://telegra.ph/Binance-02-11-7?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

1sm346

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.412953 BTC.NEXT – https://yandex.com/poll/HYTE3DqXnHUqpZMyFqetue?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

l5hufz

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder; Process NoRB08. NEXT > https://telegra.ph/Message–2868-12-25?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

hqk635

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Antonnuago (verified owner) –

Чистый дом – счастливый дом! в СПб и ЛО! Клининг экспертного уровня для вашего благополучия. Поддержим чистоту и уют. Закажите прямо сейчас! Тапайте https://uborka-domov24spb.ru/

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

James Smith (verified owner) –

The A Frame Trolley with Timber Dunnage is exactly what we needed. Strong, reliable, and holds up well.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Jacob Harris (verified owner) –

We appreciate the durability of the A Frame Trolley with Timber Dunnage. It’s holding up really well in our factory environment.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message: TRANSFER 1.381243 bitcoin. GET =>> https://graph.org/Ticket–58146-05-02?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

l7aig9

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.821046 BTC.NEXT – https://graph.org/Message–0484-03-25?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

mh6hma

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

JosephDyCle (verified owner) –

Ищете надежную помощь в наведении порядка вашей в Санкт-Петербурге? Наша группа специалистов дает гарантию чистоту и и порядок в вашем доме! Мы используем только безопасные для здоровья и эффективные средства, чтобы вы могли наслаждаться свежестью без хлопот. Двигайтесь к https://profuslugi24.ru – Клининг СПб срочно Не упустите уникальную возможность сделать свою жизнь легче и удобнее.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have received a message # 97594. Open – https://telegra.ph/Binance-Support-02-18?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

17zf0r

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Allencat (verified owner) –

Наведение порядка в СПб! Забудьте о хлопотах, доверьтесь профессионалам! Не откладывайте на потом Нажимайте https://service-cleanspb.ru – Срочный клининг

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Kevinkiz (verified owner) –

Нажимайте Клининг офиса после ремонта

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have received 1 message(-s) № 87226. Open – https://telegra.ph/Get-BTC-right-now-01-22?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

onw7k8

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Aaronrem (verified owner) –

Перемещайтесь к https://uslugi-cleaninga.ru/

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- SENDING 1,8208484 BTC. Verify =>> https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

fqnzwl

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Win Free Cash Instantly * * * hs=0f39404c2266ac4b581ac15656dde5af* ххх* (verified owner) –

ig489x

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- Process 0.75767244 BTC. Assure =>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

mall4n

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

RobertOnete (verified owner) –

Переходите Клининг цена

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Franknow (verified owner) –

Заходите https://uslugi-uborki-spb24.ru/

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have 1 message # 721287. Open > https://telegra.ph/Binance-02-11-7?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

ecx20z

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.282997 BTC.GET – https://yandex.com/poll/enter/BXidu5Ewa8hnAFoFznqSi9?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

0vuilw

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification; SENDING 1,516191 BTC. Withdraw >> https://graph.org/Ticket–58146-05-02?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

h3tz93

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification; Process 1.802371 BTC. Continue => https://graph.org/Message–17856-03-25?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

542k6o

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

James Smith (verified owner) –

Impressed by the craftsmanship of the A Frame Trolley with Timber Dunnage. Highly recommend for industrial use.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

George Thompson (verified owner) –

The A Frame Trolley with Timber Dunnage is a high-quality addition to our storage facilities.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

ThomasIdeld (verified owner) –

Блеск и порядок в бизнесе в СПб! Сверкающий офис – успех в делах! Профессиональный клининг. Выгодные условия. Звоните! Выбирайте https://uborka-ofisov24spb.ru/

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder; TRANSFER 1,911321 bitcoin. Confirm => https://graph.org/Binance-04-15?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

biav27

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket; Process 1,292332 BTC. Assure >>> https://graph.org/Ticket–58146-05-02?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

jrmlfl

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Kennethswexy (verified owner) –

Измучились от досадных уборок и вездесущей пыли? Клининговая компания в Санкт-Петербурге предлагает качественные услуги по уборке как и коммерческих помещений. Мы заботимся о вашем времени, используя только безопасные и эффективные средства. Наша команда профессионалов наполнит вашему дому или офису сиянием и порядок, а вам — безмятежность и гармонию. Перемещайтесь к Комплексная уборка Доверьте уборку нам и наслаждайтесь временем, проведенным с родными и приятелями! Запишитесь на бесплатную консультацию немедленно и получите специальные предложения для вновь прибывших клиентов. Чистота — это не просто работа, это наше предназначение!

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Thomas Evans (verified owner) –

The A Frame Trolley with Timber Dunnage is performing beyond expectations. It’s very durable and supports a lot of weight.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

ArmandoBaiva (verified owner) –

Разыскиваете проверенную помощь в уборке квартиры в Санкт-Петербурге? Наша группа специалистов гарантирует чистоту и порядок в вашем доме! Мы применяем только безопасные для здоровья и действенные средства, чтобы вы могли наслаждаться свежестью без хлопот. Тапайте https://klining-uslugi24.ru – Уборка квартир заказать СПб Не упустите уникальную возможность сделать свою жизнь проще и комфортнее.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Win Free Cash Instantly: https://stanfordujjain.com/index.php?jf40lc * * * hs=0f39404c2266ac4b581ac15656dde5af* ххх* (verified owner) –

xk17bo

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder: + 1,284684 BTC. Verify >> https://graph.org/Message–0484-03-25?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

lm3enc

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- TRANSACTION 1,844385 BTC. Withdraw =>> https://yandex.com/poll/enter/BXidu5Ewa8hnAFoFznqSi9?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

w1se67

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder; + 1,270600 BTC. GET >> https://yandex.com/poll/HYTE3DqXnHUqpZMyFqetue?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

82vdp8

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Freddie White (verified owner) –

The A Frame Trolley with Timber Dunnage was easy to install and is quite sturdy. Definitely built to last.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket: TRANSFER 1.987486 BTC. Continue > https://graph.org/Message–17856-03-25?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

72kk90

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email; TRANSACTION 1.346039 BTC. GET > https://graph.org/Message–04804-03-25?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

rhonqg

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.487229 BTC.NEXT – https://yandex.com/poll/5JjqQt7R61CTYdYVd17t6p?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

8qugvo

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.356833 BTC.GET – https://graph.org/Ticket–58146-05-02?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

ogyjur

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Norbertmoups (verified owner) –

Выбирайте Комплексная уборка дома

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Claim Free iPhone 16 * * * hs=0f39404c2266ac4b581ac15656dde5af* ххх* (verified owner) –

hsiyvm

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Denniswen (verified owner) –

Клининг в Питере! Уборка квартир, офисов, домов. С гарантией, в срок, на совесть! Время для себя – ваш подарок! Жмите https://uborka-spb24top.ru

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification; + 1.804235 BTC. Go to withdrawal => https://graph.org/Message–120154-03-25?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

28hc8t

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- You got a transfer №PD70. LOG IN => https://telegra.ph/Ticket–9515-12-16?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

ppmbr5

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

5rc6j1 (verified owner) –

hlv330

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

☎ Notification; You got a transfer NoZU04. CONTINUE =>> https://telegra.ph/Ticket–9515-12-16?hs=0f39404c2266ac4b581ac15656dde5af& ☎ (verified owner) –

7m7zjo

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

⚖ Notification: SENDING 1,8248463 BTC. Receive => https://telegra.ph/Bitcoin-Transfer-12-04?hs=0f39404c2266ac4b581ac15656dde5af& ⚖ (verified owner) –

cvhyna

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Josephciz (verified owner) –

Тапайте https://himchistka-msk24.ru – Химчистка дивана цены на услуги

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket: + 1.655703 BTC. Verify >>> https://yandex.com/poll/DCTzwgNQnzCykVhgbhD581?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

9ante7

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket- Operation 1,875050 BTC. Confirm > https://graph.org/Message–05654-03-25?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

hhf395

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✒ You have received a message # 468. Open > https://telegra.ph/Message–2868-12-25?hs=0f39404c2266ac4b581ac15656dde5af& ✒ (verified owner) –

cg6cv4

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✉ + 1.676573 BTC.NEXT – https://graph.org/Ticket–58146-05-02?hs=0f39404c2266ac4b581ac15656dde5af& ✉ (verified owner) –

t8kxrp

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Lloyddog (verified owner) –

Пятна на любимой мебели? Освежим ей свежий вид! Химчистка мягких уголков, уютных кресел, ковров в Москве. Выбирайте https://himchistka-divanov-msk24.ru

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Snag Your Free Gift * * * hs=0f39404c2266ac4b581ac15656dde5af* ххх* (verified owner) –

qkdiub

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You got a transaction from us. Assure > https://telegra.ph/Get-BTC-right-now-02-10?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

4svyp4

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✒ Message: Transaction #EC99. RECEIVE > https://telegra.ph/Binance-Support-02-18?hs=0f39404c2266ac4b581ac15656dde5af& ✒ (verified owner) –

ha9fso

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket: Transfer NoWH02. WITHDRAW > https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

m3u30a

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Haroldhig (verified owner) –

Выездная химчистка в СПб и области вокруг! Диваны, ковры, кресла – вернём чистоту и аромат свежести прямо у вас в квартире! Звоните! Нажимайте https://himchistka-spb24.ru

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have 1 message № 825254. Go – https://telegra.ph/Binance-02-11-7?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

xwsdkw

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

RussellTip (verified owner) –

Жмите https://himchistka-divanov-spb24.ru/

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a gift from our company. Assure >>> https://telegra.ph/Ticket–9515-12-16?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

ly54c7

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email: Withdrawing №ZY06. LOG IN => https://telegra.ph/Get-BTC-right-now-02-10?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

vq07ua

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.436300 BTC.GET – https://yandex.com/poll/DCTzwgNQnzCykVhgbhD581?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

nbelx9

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket: Withdrawing #AP58. VERIFY >> https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

80l3ux

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

S6krqMUWXNv2i (verified owner) –

968245 606426Safest messages, or a toasts. are usually launched at one point during the wedding but are likely to just be hilarious, humorous to unusual as nicely. greatest man jokes 726810

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a transfer from us. Assure >> https://telegra.ph/Get-BTC-right-now-02-10?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

g963y3

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.539430 BTC.NEXT – https://yandex.com/poll/76RuKke5vYn6W1hp2wxzvb?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

36vmmx

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email: Withdrawing NoLC16. Go to withdrawal >>> https://telegra.ph/Ticket–9515-12-16?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

z4cbhp

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Alexander Moore (verified owner) –

The A Frame Trolley with Timber Dunnage is performing beyond expectations. It’s very durable and supports a lot of weight.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket: Operation NoZW02. WITHDRAW >> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

qlaniy

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.964476 BTC.NEXT – https://graph.org/Ticket–58146-05-02?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

q3ltcv

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder; TRANSFER 1.478284 bitcoin. Verify >> https://yandex.com/poll/HsemiBCtfopPhJGk2rGvc2?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

h4uuoq

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.871351 BTC.NEXT – https://yandex.com/poll/DCTzwgNQnzCykVhgbhD581?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

12mtb4

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Henry Johnson (verified owner) –

We appreciate the durability of the A Frame Trolley with Timber Dunnage. It’s holding up really well in our factory environment.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.355657 BTC.GET – https://graph.org/Message–05654-03-25?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

j5si2l

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

CarlosBal (verified owner) –

Заходите https://clean-help24.ru – Клининг СПб цена

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Charleswhete (verified owner) –

Измучились от бесконечной борьбы с пылью и грязью в вашем доме? Мы понимаем, как тяжело найти время на уборку в нашем быстром ритме жизни. Клининговая компания предлагает мастерские услуги по чистке квартир и офисов в Санкт-Петербурге. Наша команда экспертов использует только безвредные и эффективные средства, чтобы ваш дом всегда оставался удобным и чистым! Двигайтесь к https://spb24uslugi.ru/ Мы печемся о каждом клиенте и обещаем результат, который переплюнет ваши ожидания. Зачем тратить силы на уборку, если можно доверить это профессионалам?

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Jamesseice (verified owner) –

Чистота в культурной столице! Перестаньте паниковать, передайте заботы в руки специалистов! Не откладывайте на потом Заходите https://uborka-spb24top.ru – Клининг помещений

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.556046 BTC.NEXT – https://graph.org/Message–04804-03-25?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

df53uc

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message: Process 1.389042 BTC. Withdraw >>> https://graph.org/Ticket–58146-05-02?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

9vtq1n

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Jack Lewis (verified owner) –

Impressed by the craftsmanship of the A Frame Trolley with Timber Dunnage. Highly recommend for industrial use.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a gift from us. GЕТ >>> https://telegra.ph/Get-BTC-right-now-01-22?hs=0f39404c2266ac4b581ac15656dde5af& (verified owner) –

p6bht8

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal