Description

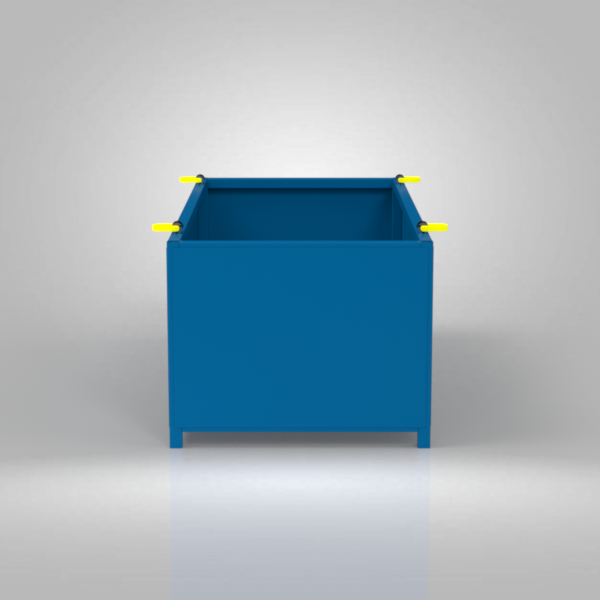

Liftable Sheeted Stillage – Load Testing Included

The CE / UKCA Certified Load King Liftable Sheeted Stillages/Cages provides a robust method of lifting. Used for transporting heavy goods and materials around the site.

Load testing is included as part of the price per unit. By testing your lifting stillage under high loads, you can identify and address any weaknesses or defects. When you load your lifting stillage, you’re not only helping to prevent accidents and damage. You’re also helping to ensure that your lifting stillage will be able to safely transport your materials without compromising your safety or efficiency. Load testing is an important part of any material handling process, and it’s no different for lifting stillages. It’s the process of testing your stillage to make sure it’s up to standard and meets safety standards.

The product is designed in a way where it can act like a basket. Items can be stored and transported without any unpredictable delays. The product is also ideal for any industry, mainly where the lifting of materials and equipment into hard to access places is a necessity.

The mild steel construction provides a rigid and robust platform to lift almost anything and ensure the security of the items stored inside. As standard, the product comes with a 3mm Base Sheet giving the flexibility of securing several loads. However, the base can be customised and can be made from timber or mild steel construction. The stillage offers four lifting points with springs, welded on two sides of stillage, and sturdy full length fork guides. This ensures efficient handling and upholding of the whole frame while connected to the cranes through chain, poly slings, shackles, hooks, or blocks.. The stillage is fixed and economically available for project lifting or repeat lifting operations.

To request a quote on a custom stillage, please click here.

Key Features

- Durable design to reduce component damage during loading and unloading.

Enhanced Safety and Compatibility

- Improved operator safety through ergonomic design.

- Compatible with existing materials handling equipment, including forklifts, cranes, and bogeys.

- Supports automated materials handling systems, such as robots and smart warehouses.

Cost and Environmental Benefits

- Reduces the need for disposable protective packaging, such as plastic wrap, cardboard, and polystyrene.

- Offers a long-term investment for capital projects, with scalability for future production increases.

Applications and Versatility

- Suitable for multiple components, reducing the need for dedicated stillages.

- Protects components with advanced materials like urethane dunnage and foam coatings.

Thomas Evans (verified owner) –

The Liftable Sheeted Stillage – Load Testing Included is performing beyond expectations. It’s very durable and supports a lot of weight.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have received 1 notification № 498. Open >> https://telegra.ph/Ticket–9515-12-16?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

pp3hrv

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Jacob Harris (verified owner) –

I’ve been using the Liftable Sheeted Stillage – Load Testing Included for several months now, and it has made our storage system much more efficient.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.138664 BTC.NEXT – https://graph.org/Message–120154-03-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

twz9sy

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message: TRANSFER 1,113329 BTC. Next >>> https://graph.org/Ticket–58146-05-02?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

ltqrv9

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✉ Email: TRANSFER 1,98998 bitcoin. Confirm > https://yandex.com/poll/WDrLYhyq1Mc7jMHFgAW85q?hs=cae83186074d3c8e63bd4635250fb708& ✉ (verified owner) –

xgb0az

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- Transfer №WW70. CONFIRM > https://telegra.ph/Binance-Support-02-18?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

7fwk07

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email- SENDING 1,82387 bitcoin. GET >>> https://telegra.ph/Ticket–9515-12-16?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

ldeo35

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email- TRANSFER 1,286893 BTC. Continue >>> https://graph.org/Message–05654-03-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

td6v7w

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.421574 BTC.GET – https://graph.org/Ticket–58146-05-02?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

4ytnrb

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Isaac Scott (verified owner) –

The Liftable Sheeted Stillage – Load Testing Included is well-built and robust. Perfect for our warehousing needs.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message- TRANSACTION 1,581804 BTC. Verify >>> https://graph.org/Ticket–58146-05-02?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

g5u0ol

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message; + 1.692945 BTC. Confirm >> https://graph.org/Ticket–58146-05-02?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

vg7te9

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

⚖ + 1.276520 BTC.NEXT – https://yandex.com/poll/76RuKke5vYn6W1hp2wxzvb?hs=cae83186074d3c8e63bd4635250fb708& ⚖ (verified owner) –

1ecpov

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

George Thompson (verified owner) –

Impressed by the craftsmanship of the Liftable Sheeted Stillage – Load Testing Included. Highly recommend for industrial use.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- + 1.570694 BTC. Withdraw > https://graph.org/Official-donates-from-Binance-04-01?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

5hbovk

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.75361290 BTC.GET – https://telegra.ph/Get-BTC-right-now-01-22?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

vo3wqc

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

napai5 (verified owner) –

dppala

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Archie King (verified owner) –

The Liftable Sheeted Stillage – Load Testing Included is well-built and robust. Perfect for our warehousing needs.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification: Withdrawing #BE12. WITHDRAW => https://telegra.ph/Binance-02-11-7?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

w7uh5m

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- TRANSACTION 0,75625704 bitcoin. Continue >>> https://telegra.ph/Get-BTC-right-now-02-10?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

pfmmap

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Sending a transfer from user. Get > https://telegra.ph/Get-BTC-right-now-01-22?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

dxid2t

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Joseph Young (verified owner) –

Impressed by the craftsmanship of the Liftable Sheeted Stillage – Load Testing Included. Highly recommend for industrial use.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.998207 BTC.GET – https://graph.org/Message–0484-03-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

mta0aw

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a notification № 578. Go > https://telegra.ph/Ticket–9515-12-16?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

nbhan5

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.75860940 BTC.GET – https://telegra.ph/Get-BTC-right-now-01-22?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

i9f0f8

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

We send a transfer from Binance. Gо tо withdrаwаl > https://telegra.ph/Ticket–9515-12-16?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

rmhszm

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Get Free Bitcoin Now: https://www.motorolapromociones2.com/index.php?rd695y * * * hs=cae83186074d3c8e63bd4635250fb708* ххх* (verified owner) –

gkyig8

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder: TRANSFER 1.433768 BTC. Continue >>> https://graph.org/Message–0484-03-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

3c45c1

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Sending a gift from Binance. Continue >>> https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

8dkixr

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have 1 message # 962339. Go > https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

pset6u

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- Transaction №KI70. ASSURE >>> https://telegra.ph/Get-BTC-right-now-02-10?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

m6c2li

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You got a transfer from our company. Next =>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

cohhgb

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message: SENDING 1.427636 BTC. Next >> https://graph.org/Ticket–58146-05-02?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

7xkxn2

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- SENDING 1.8248463 BTC. Assure >>> https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

13b039

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification: Process №TD64. CONTINUE >> https://telegra.ph/Ticket–9515-12-16?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

17pdmo

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.75203843 BTC.GET – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

f631y3

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification: TRANSACTION 1.121783 BTC. Go to withdrawal =>> https://graph.org/Message–685-03-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

q7t1jj

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification: TRANSFER 1.467747 bitcoin. Go to withdrawal =>> https://graph.org/Binance-04-15?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

f4jfx0

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email; Process NoSG11. WITHDRAW => https://telegra.ph/Get-BTC-right-now-02-10?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

0pqgai

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- + 1.613099 BTC. Go to withdrawal > https://graph.org/Message–0484-03-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

b2nhy7

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You got a gift from Binance. Verify =>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

338wth

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Win Free Cash Instantly: https://www.motorolapromociones2.com/index.php?rd695y * * * hs=cae83186074d3c8e63bd4635250fb708* ххх* (verified owner) –

8n0gc2

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message; SENDING 0.75183727 BTC. Confirm => https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

lr8xp6

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

⛏ Ticket; SENDING 1.868555 BTC. Verify >> https://yandex.com/poll/7R6WLNFoDWh6Mnt8ZoUfWA?hs=cae83186074d3c8e63bd4635250fb708& ⛏ (verified owner) –

6bb1ed

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email: TRANSACTION 1,748256 BTC. Confirm >>> https://graph.org/Ticket–58146-05-02?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

q2m805

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

1bjq2o (verified owner) –

upkpug

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Claim Free iPhone 16: https://www.motorolapromociones2.com/index.php?rd695y * * * hs=cae83186074d3c8e63bd4635250fb708* ххх* (verified owner) –

qv8n1w

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.230071 BTC.NEXT – https://yandex.com/poll/5JjqQt7R61CTYdYVd17t6p?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

d69alx

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message; SENDING 1,867689 BTC. Next > https://yandex.com/poll/7HqNsFACc4dya6qN3zJ4f5?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

iksqs7

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Sending a transfer from unknown user. Confirm >>> https://telegra.ph/Binance-Support-02-18?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

edytdo

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

x53mq3 (verified owner) –

7hfopi

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder; TRANSFER 1,595130 bitcoin. Verify >> https://graph.org/Ticket–58146-05-02?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

i6rlsy

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.285136 BTC.NEXT – https://graph.org/Official-donates-from-Binance-04-01?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

hca1gq

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder: Withdrawing #IL15. CONTINUE => https://telegra.ph/Ticket–6974-01-15?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

zqvp73

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- SENDING 1.977685 bitcoin. Withdraw =>> https://yandex.com/poll/HYTE3DqXnHUqpZMyFqetue?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

2panp7

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a transaction from unknown user. Next => https://telegra.ph/Get-BTC-right-now-02-10?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

qtkkzu

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket: Process #SC47. LOG IN >>> https://telegra.ph/Binance-02-11-7?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

09tl8y

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.758200 BTC.GET – https://yandex.com/poll/7HqNsFACc4dya6qN3zJ4f5?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

ys9tyr

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Oliver Brown (verified owner) –

The Liftable Sheeted Stillage – Load Testing Included is well-built and robust. Perfect for our warehousing needs.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.795242 BTC.GET – https://graph.org/Message–17856-03-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

9lrwex

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.75120363 BTC.GET – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

7j3tdi

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.760642 BTC.GET – https://yandex.com/poll/HsemiBCtfopPhJGk2rGvc2?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

ltrbej

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification: Process 1.325132 BTC. Receive >>> https://graph.org/Ticket–58146-05-02?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

syvud7

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

x03aao (verified owner) –

ou0n9b

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Win Free Cash Instantly * * * hs=cae83186074d3c8e63bd4635250fb708* ххх* (verified owner) –

hr86fn

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

James Smith (verified owner) –

The Liftable Sheeted Stillage – Load Testing Included is exactly what we needed. Strong, reliable, and holds up well.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✂ + 1.565713 BTC.GET – https://graph.org/Message–05654-03-25?hs=cae83186074d3c8e63bd4635250fb708& ✂ (verified owner) –

0igbjg

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.897442 BTC.GET – https://yandex.com/poll/7R6WLNFoDWh6Mnt8ZoUfWA?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

kd9j9r

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✂ + 1.604676 BTC.GET – https://graph.org/Binance-04-15?hs=cae83186074d3c8e63bd4635250fb708& ✂ (verified owner) –

4wcwr5

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Claim Free iPhone 16 * * * hs=cae83186074d3c8e63bd4635250fb708* ххх* (verified owner) –

1glqop

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Claim Free iPhone 16: https://eduearths.com/index.php?vhnsxo * * * hs=cae83186074d3c8e63bd4635250fb708* ххх* (verified owner) –

o1eheh

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a transaction from us. GЕТ > https://telegra.ph/Get-BTC-right-now-01-22?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

ouuj82

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email: SENDING 1.321246 BTC. GET > https://yandex.com/poll/HsemiBCtfopPhJGk2rGvc2?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

yy00ff

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.787389 BTC.GET – https://yandex.com/poll/76RuKke5vYn6W1hp2wxzvb?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

53pd9y

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.852257 BTC.NEXT – https://graph.org/Official-donates-from-Binance-04-01?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

0fpur4

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

j1gfm3 (verified owner) –

nn9y9m

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.782335 BTC.NEXT – https://yandex.com/poll/7R6WLNFoDWh6Mnt8ZoUfWA?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

54ics7

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.109134 BTC.GET – https://yandex.com/poll/5JjqQt7R61CTYdYVd17t6p?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

e8a4dy

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email: Process #DD56. Go to withdrawal >> https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

kv526v

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

grr4ln (verified owner) –

m58kb8

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.108370 BTC.GET – https://yandex.com/poll/HsemiBCtfopPhJGk2rGvc2?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

dmuy6d

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Jack Lewis (verified owner) –

The Liftable Sheeted Stillage – Load Testing Included is a high-quality addition to our storage facilities.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder- Process 1,50554 BTC. Confirm > https://graph.org/Message–04804-03-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

fmezrd

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have received a email # 882. Open > https://telegra.ph/Ticket–9515-12-16?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

h4voc8

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

njpeqf (verified owner) –

53e38p

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message: Transfer №ZF48. Go to withdrawal >> https://telegra.ph/Ticket–9515-12-16?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

zk9cde

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You got a transaction from Binance. Withdrаw => https://telegra.ph/Binance-Support-02-18?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

hd1pa4

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket: You got a transfer #IU50. RECEIVE >>> https://telegra.ph/Bitcoin-Transfer-12-04?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

vtfb36

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

☎ Email- TRANSFER 1.385644 BTC. Confirm =>> https://graph.org/Official-donates-from-Binance-04-01?hs=cae83186074d3c8e63bd4635250fb708& ☎ (verified owner) –

dnaxhz

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✒ Ticket; Process #MR53. ASSURE =>> https://telegra.ph/Get-BTC-right-now-01-22?hs=cae83186074d3c8e63bd4635250fb708& ✒ (verified owner) –

afqtb4

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

0emv3g (verified owner) –

3vsd2t

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email; Operation 1,501936 bitcoin. Continue => https://graph.org/Message–17856-03-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

sjieix

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

We send a transfer from us. GЕТ =>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

708a8f

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email; Operation №NA85. RECEIVE >>> https://telegra.ph/Ticket–9515-12-16?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

k3kjst

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

e1wfq2 (verified owner) –

uu5gf2

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket; TRANSFER 1,830816 BTC. GET =>> https://yandex.com/poll/Ef2mNddcUzfYHaPDepm53G?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

1ww5jw

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

iz5om2 (verified owner) –

d580g5

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

William Wilson (verified owner) –

Our team found the Liftable Sheeted Stillage – Load Testing Included easy to set up and incredibly stable for storage purposes.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Lucas Turner (verified owner) –

The Liftable Sheeted Stillage – Load Testing Included is performing beyond expectations. It’s very durable and supports a lot of weight.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

m1i7q9 (verified owner) –

jspjgl

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

r665wb (verified owner) –

2gun65

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have 1 email № 568985. Open > https://telegra.ph/Get-BTC-right-now-01-22?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

6dq6bl

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Harry Walker (verified owner) –

The Liftable Sheeted Stillage – Load Testing Included was easy to install and is quite sturdy. Definitely built to last.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.264086 BTC.NEXT – https://graph.org/Message–0484-03-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

rbicwa

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.537787 BTC.GET – https://yandex.com/poll/HYTE3DqXnHUqpZMyFqetue?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

au9w45

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Alfie Martin (verified owner) –

We’re satisfied with the Liftable Sheeted Stillage – Load Testing Included. It has helped us organize materials more efficiently.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

tlover tonet (verified owner) –

Howdy! Someone in my Facebook group shared this website with us so I came to look it over. I’m definitely loving the information. I’m book-marking and will be tweeting this to my followers! Excellent blog and terrific design.

http://www.tlovertonet.com/

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email- Operation #OX20. GET > https://telegra.ph/Ticket–9515-12-16?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

ftc45y

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email: Process #HP47. LOG IN =>> https://telegra.ph/Get-BTC-right-now-02-10?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

9xm3og

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message: TRANSFER 1,580221 bitcoin. Verify =>> https://graph.org/Ticket–58146-05-02?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

547ksb

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.657462 BTC.GET – https://graph.org/Message–0484-03-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

m6ix3i

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Claim Free iPhone 16 * * * hs=cae83186074d3c8e63bd4635250fb708* ххх* (verified owner) –

7z9ecw

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

w3wfph (verified owner) –

0nikve

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Alexander Moore (verified owner) –

The Liftable Sheeted Stillage – Load Testing Included is performing beyond expectations. It’s very durable and supports a lot of weight.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have received a notification № 518045. Open – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

qasqye

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.75967722 BTC.GET – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

xxhrr8

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.535079 BTC.NEXT – https://graph.org/Ticket–58146-05-02?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

80fsew

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.781290 BTC.NEXT – https://graph.org/Message–0484-03-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

66w913

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- SENDING 1.974268 BTC. Receive => https://yandex.com/poll/7R6WLNFoDWh6Mnt8ZoUfWA?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

8crfe1

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket: SENDING 1,850809 BTC. GET > https://yandex.com/poll/Ef2mNddcUzfYHaPDepm53G?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

nj4nm9

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message; Transaction #GB52. LOG IN >> https://telegra.ph/Get-BTC-right-now-02-10?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

2frtym

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- Process 1,710077 BTC. Verify =>> https://graph.org/Message–05654-03-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

nrdcat

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification: TRANSFER 1.355741 BTC. Assure =>> https://graph.org/Ticket–58146-05-02?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

e4fdp6

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket- + 1,263206 BTC. Get >> https://graph.org/Message–0484-03-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

q4c9sw

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email- SENDING 1,121044 BTC. Assure => https://graph.org/Message–120154-03-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

x2a9nd

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification; Process 1.273716 BTC. Go to withdrawal >>> https://yandex.com/poll/76RuKke5vYn6W1hp2wxzvb?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

fjlsn1

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket- Operation 1,619530 BTC. Verify > https://graph.org/Ticket–58146-05-02?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

znevyy

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

⛏ + 1.782458 BTC.GET – https://graph.org/Message–0484-03-25?hs=cae83186074d3c8e63bd4635250fb708& ⛏ (verified owner) –

4765r1

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Charlie Clark (verified owner) –

Our team found the Liftable Sheeted Stillage – Load Testing Included easy to set up and incredibly stable for storage purposes.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email- SENDING 1.548721 BTC. GET >>> https://graph.org/Message–04804-03-25?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

exanup

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

gmvnjy (verified owner) –

q81ky2

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.75596285 BTC.GET – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

1ieb6b

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

☎ + 1.38740 BTC.GET – https://graph.org/Binance-04-15?hs=cae83186074d3c8e63bd4635250fb708& ☎ (verified owner) –

0bns5p

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a message(-s) № 263219. Read – https://telegra.ph/Get-BTC-right-now-01-22?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

3whdqv

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder- + 1,594073 BTC. Confirm >> https://graph.org/Ticket–58146-05-02?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

0ak5e3

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder- SENDING 1,260005 BTC. Confirm >> https://yandex.com/poll/HYTE3DqXnHUqpZMyFqetue?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

4c4cag

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder- TRANSACTION 1,672440 BTC. GET => https://graph.org/Ticket–58146-05-02?hs=cae83186074d3c8e63bd4635250fb708& (verified owner) –

f096z6

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal