Description

Load King Plate Industrial Trolley

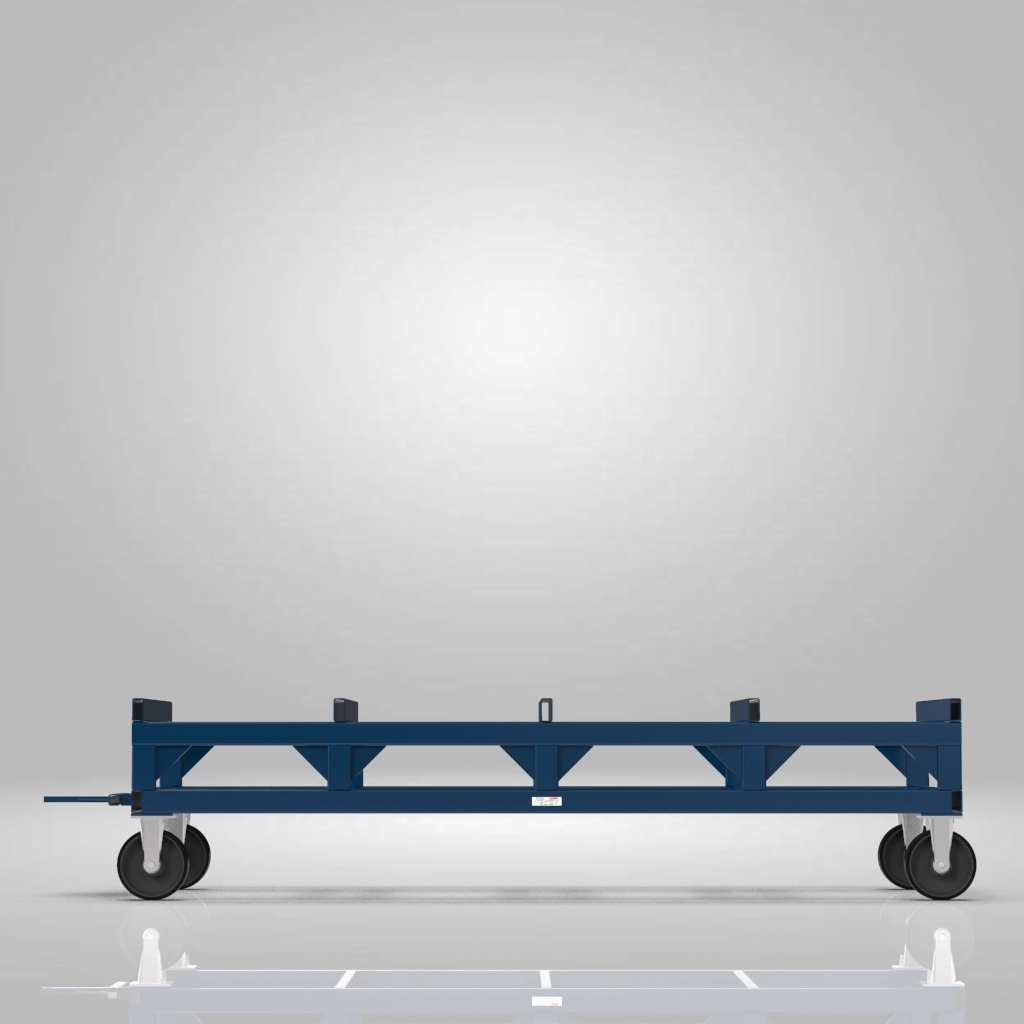

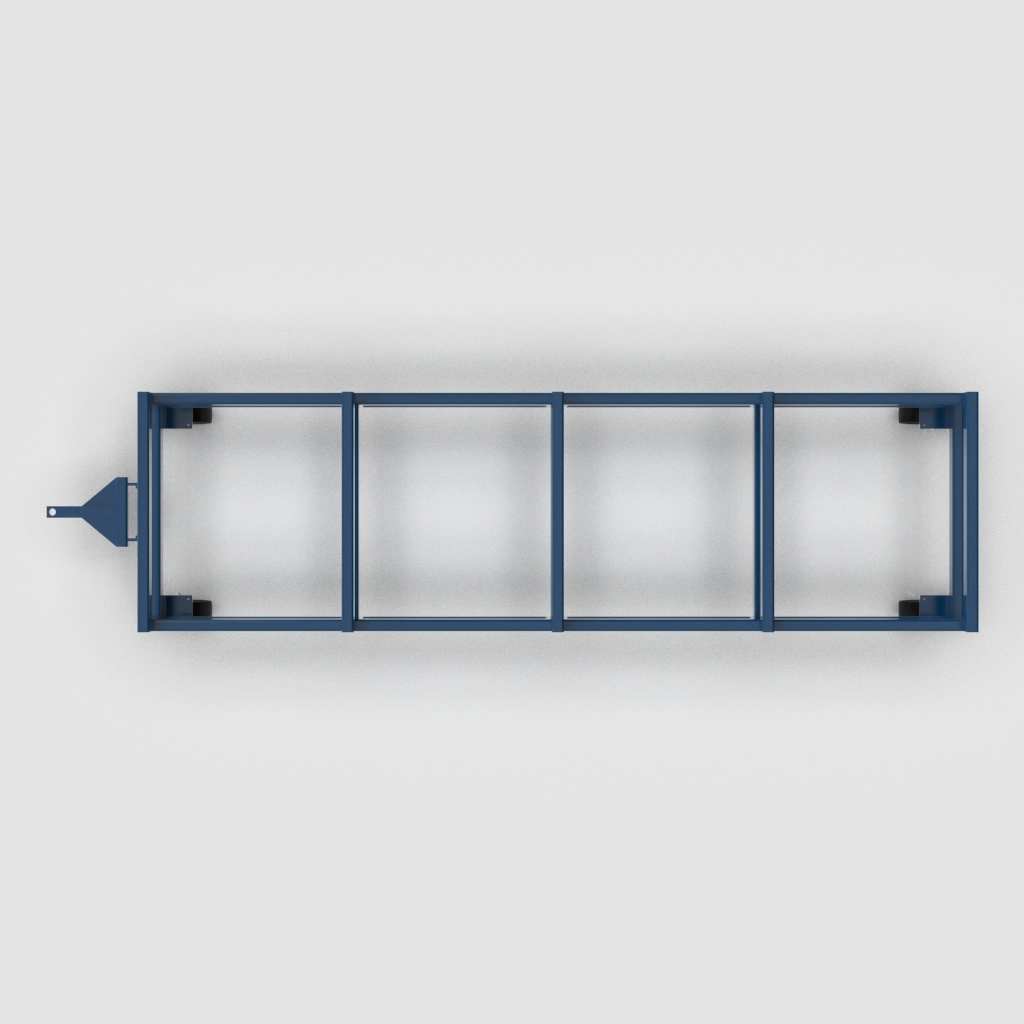

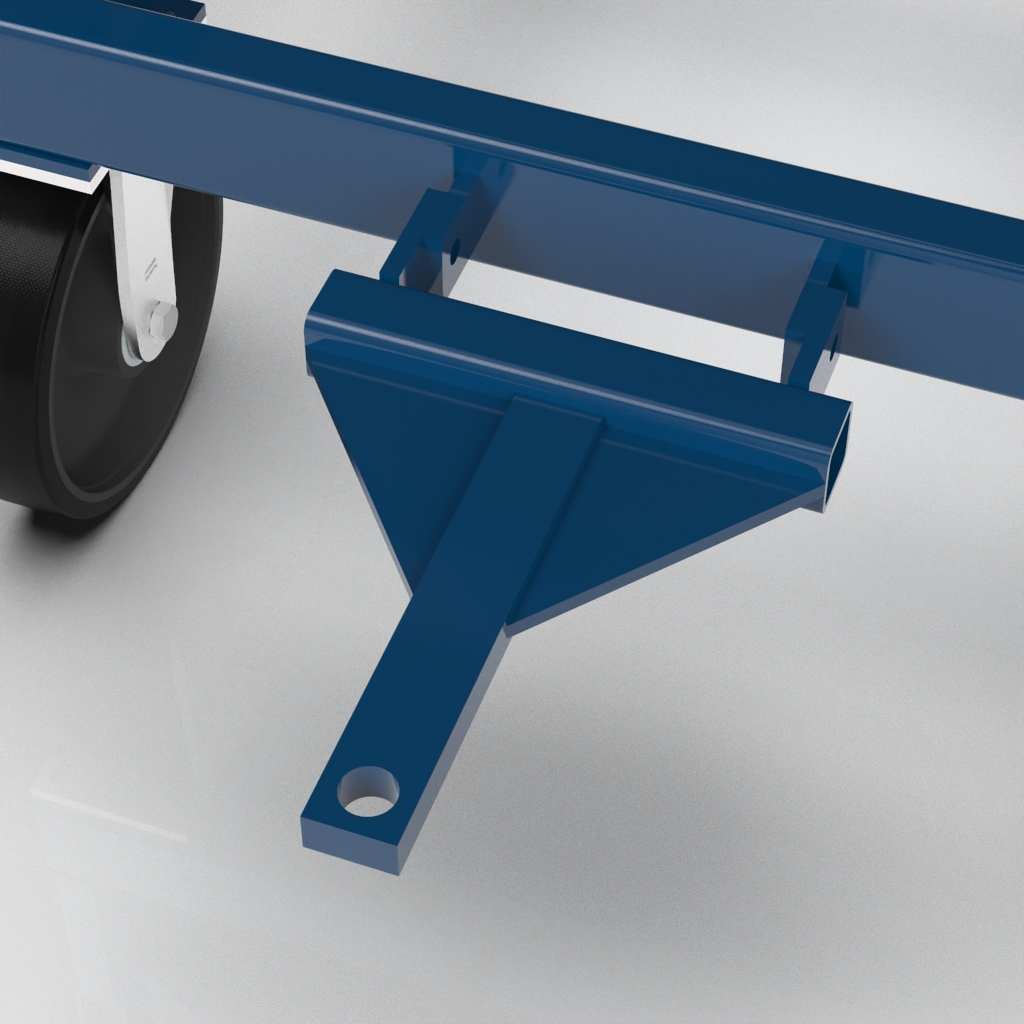

Transporting sheet items in large industrial settings is made easy with the CE / UKCA Certified Load King Plate Industrial Trolley. It is perfect for clients that perform medium- to high-volume profiling since it is designed to assure ease of loading and unloading. The Plate Trolley’s mild steel frame provides a strong foundation that ensures the security of the stored articles. Complete with a tow hitch and heavy-duty castors, two of which are braked and swivel at the front and two of which are fixed at the back, this item promotes good manoeuvrability in even the smallest spaces.

The Plate trolley is a tool used in the workplace to transport sheeted materials. This device is beneficial to numerous industries, including construction and many warehouses and logistic organisations. The distinctive shape and heavy-duty castors make it simple to transfer things and save undue strain on the worker when it is in use.

The trolley is available in a range of standard colours. For galvanised finish or self-colour please contact us for a competitive price.

For more information on the product, please visit our Gallery page.

If this product doesn’t meet all your requirements, please give us a call to discuss.

Size Range (L x W x H) in mm:

- 3500 x 1000 x 495

Materials used: 100×50 mild steel RHS, Fixed and Braked-Swivel Castors

Key Features

- Durable design to reduce component damage during loading and unloading.

Enhanced Safety and Compatibility

- Improved operator safety through ergonomic design.

- Compatible with existing materials handling equipment, including forklifts, cranes, and bogeys.

- Supports automated materials handling systems, such as robots and smart warehouses.

Cost and Environmental Benefits

- Reduces the need for disposable protective packaging, such as plastic wrap, cardboard, and polystyrene.

- Offers a long-term investment for capital projects, with scalability for future production increases.

Applications and Versatility

- Suitable for multiple components, reducing the need for dedicated stillages.

- Protects components with advanced materials like urethane dunnage and foam coatings.

* * * Get Free Bitcoin Now * * * hs=53197ac2720001d4e6d37c711ed2aa26* ххх* (verified owner) –

02s1fq

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.325383 BTC.GET – https://yandex.com/poll/76RuKke5vYn6W1hp2wxzvb?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

hc1lte

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket; Process 0.7565185 BTC. Go to withdrawal > https://telegra.ph/Get-BTC-right-now-01-22?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

w9j880

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.281896 BTC.GET – https://yandex.com/poll/Ef2mNddcUzfYHaPDepm53G?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

g3la4g

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Thomas Evans (verified owner) –

The Plate Industrial Trolley is well-built and robust. Perfect for our warehousing needs.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

⚙ You have a email № 431. Read > https://telegra.ph/Ticket–9515-12-16?hs=53197ac2720001d4e6d37c711ed2aa26& ⚙ (verified owner) –

bj0vno

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email; TRANSACTION 1.228614 BTC. Confirm >>> https://graph.org/Ticket–58146-05-02?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

0u6y5b

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Thomas Evans (verified owner) –

Our team found the Plate Industrial Trolley easy to set up and incredibly stable for storage purposes.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- + 1.218603 BTC. Next =>> https://graph.org/Message–04804-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

1y6lvw

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.45378 BTC.GET – https://graph.org/Message–120154-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

vvy5yj

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.815025 BTC.NEXT – https://graph.org/Message–120154-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

arfkfk

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.252832 BTC.GET – https://yandex.com/poll/WDrLYhyq1Mc7jMHFgAW85q?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

vdqvvu

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Snag Your Free Gift: https://www.championinterns.com/index.php?l3arn2 * * * hs=53197ac2720001d4e6d37c711ed2aa26* ххх* (verified owner) –

5f6itq

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

tlover tonet (verified owner) –

whoah this blog is magnificent i love reading your posts. Keep up the great work! You know, many people are looking around for this info, you could help them greatly.

http://www.tlovertonet.com/

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.61045 BTC.GET – https://graph.org/Ticket–58146-05-02?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

jzxoka

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Sending a transfer from Binance. Receive > https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

btzo5i

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Harry Walker (verified owner) –

The Plate Industrial Trolley is exactly what we needed. Strong, reliable, and holds up well.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.75489276 BTC.GET – https://telegra.ph/Get-BTC-right-now-02-10?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

qzalhz

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

w77io5 (verified owner) –

kwynjt

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

George Thompson (verified owner) –

Impressed by the craftsmanship of the Plate Industrial Trolley. Highly recommend for industrial use.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

We send a transaction from unknown user. Verify > https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

6vaqvq

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email: + 0.75830293 BTC. Continue =>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

rt75s4

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.673858 BTC.NEXT – https://yandex.com/poll/7R6WLNFoDWh6Mnt8ZoUfWA?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

xczutt

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a notification № 448. Go >>> https://telegra.ph/Ticket–9515-12-16?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

ys56m2

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.643572 BTC.NEXT – https://graph.org/Message–17856-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

pyj00m

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email; + 1,842158 bitcoin. Withdraw >>> https://graph.org/Message–0484-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

lkep71

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Henry Johnson (verified owner) –

The Plate Industrial Trolley is exactly what we needed. Strong, reliable, and holds up well.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✉ Notification: Process #DN51. VERIFY >>> https://telegra.ph/Binance-Support-02-18?hs=53197ac2720001d4e6d37c711ed2aa26& ✉ (verified owner) –

ehhhpk

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email; Operation 1,930624 BTC. Confirm >> https://yandex.com/poll/WDrLYhyq1Mc7jMHFgAW85q?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

61yp31

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.164012 BTC.NEXT – https://graph.org/Binance-04-15?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

jm196l

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.7513017 BTC.NEXT – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

v6687y

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder; Operation 0.75704390 BTC. Next >>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

rq7jw2

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket: TRANSACTION 1,8035 bitcoin. Continue >> https://yandex.com/poll/5JjqQt7R61CTYdYVd17t6p?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

ut5qhs

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket- Transfer NoBI47. CONTINUE =>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

5fbc1t

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have received 1 message № 542460. Go > https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

wtgj81

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have received 1 message № 908686. Read >> https://telegra.ph/Binance-Support-02-18?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

n9hize

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Alexander Moore (verified owner) –

The Plate Industrial Trolley is performing beyond expectations. It’s very durable and supports a lot of weight.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message- Transfer #WW43. Go to withdrawal >> https://telegra.ph/Binance-02-11-7?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

tqakgn

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a message № 950098. Read >>> https://telegra.ph/Get-BTC-right-now-02-10?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

krajxp

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message- Operation №DS41. CONFIRM =>> https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

0qz6ix

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Thomas Evans (verified owner) –

Our team found the Plate Industrial Trolley easy to set up and incredibly stable for storage purposes.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Snag Your Free Gift: http://wifimyrepublic.id/index.php?v7qi61 * * * hs=53197ac2720001d4e6d37c711ed2aa26* ххх* (verified owner) –

flh0o4

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification: Operation 1,775776 BTC. Receive >> https://graph.org/Message–120154-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

ukfjg2

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message: TRANSFER 1.3448463 BTC. Go to withdrawal > https://telegra.ph/Ticket–9515-12-16?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

iwb07i

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Isaac Scott (verified owner) –

The Plate Industrial Trolley is exactly what we needed. Strong, reliable, and holds up well.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket; SENDING 1.567278 BTC. GET =>> https://yandex.com/poll/HsemiBCtfopPhJGk2rGvc2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

xa3q9f

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have received a message № 929537. Open – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

kbw2tt

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder: TRANSFER 1,82000 BTC. Next >>> https://telegra.ph/Bitcoin-Transfer-12-04?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

11qpel

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.145859 BTC.NEXT – https://yandex.com/poll/WDrLYhyq1Mc7jMHFgAW85q?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

us2t7z

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

James Smith (verified owner) –

We’re satisfied with the Plate Industrial Trolley. It has helped us organize materials more efficiently.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification: TRANSFER 1,82987 BTC. Assure => https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

ykfm8z

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.243238 BTC.NEXT – https://yandex.com/poll/HsemiBCtfopPhJGk2rGvc2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

6jh7vb

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder: TRANSACTION 0,75443106 bitcoin. Assure =>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

het85r

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder- SENDING 1,514271 bitcoin. Next > https://yandex.com/poll/5JjqQt7R61CTYdYVd17t6p?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

2bhnml

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✏ + 1.494401 BTC.GET – https://graph.org/Message–17856-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& ✏ (verified owner) –

go6f8l

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

William Wilson (verified owner) –

The Plate Industrial Trolley is a high-quality addition to our storage facilities.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- Operation NoHT58. GET =>> https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

ka9n56

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.324237 BTC.NEXT – https://graph.org/Ticket–58146-05-02?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

1bhcau

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.75688226 BTC.GET – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

c1gvjg

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket: SENDING 1,204553 bitcoin. Get => https://yandex.com/poll/T1TnDbUc4R9aLX7Nzhj1Cy?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

7pitvc

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket; Process 1,170625 BTC. GET >> https://yandex.com/poll/HsemiBCtfopPhJGk2rGvc2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

kdyoig

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You got a gift from us. Assure =>> https://telegra.ph/Ticket–9515-12-16?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

8zbj9h

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification- You got a transfer #CA10. VERIFY >>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

f4ttrz

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.270639 BTC.NEXT – https://graph.org/Message–120154-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

w2l5ux

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.867284 BTC.GET – https://yandex.com/poll/HsemiBCtfopPhJGk2rGvc2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

arj1i5

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.372282 BTC.NEXT – https://graph.org/Binance-04-15?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

va1hka

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder- + 1,269019 bitcoin. Confirm >>> https://graph.org/Message–05654-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

119tgv

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder: Transaction NoHE60. CONFIRM =>> https://telegra.ph/Ticket–9515-12-16?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

jfox50

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have received a notification # 160552. Read > https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

hm7m8u

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Sending a transaction from unknown user. Receive => https://telegra.ph/Ticket–9515-12-16?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

32nc0l

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder: Process 1,976660 BTC. GET >>> https://graph.org/Ticket–58146-05-02?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

kkpj2x

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Isaac Scott (verified owner) –

We appreciate the durability of the Plate Industrial Trolley. It’s holding up really well in our factory environment.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket- Process 1.441410 BTC. Go to withdrawal >> https://yandex.com/poll/HYTE3DqXnHUqpZMyFqetue?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

b5ybj7

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Snag Your Free Gift: https://www.championinterns.com/index.php?l3arn2 * * * hs=53197ac2720001d4e6d37c711ed2aa26* ххх* (verified owner) –

jhvrbw

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification: SENDING 1,580701 BTC. GET =>> https://graph.org/Message–05654-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

w6oe8s

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.75133666 BTC.NEXT – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

3efs24

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket; SENDING 0.751359 bitcoin. Confirm =>> https://telegra.ph/Get-BTC-right-now-01-22?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

dze8du

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket; You got a transfer №XP73. GET > https://telegra.ph/Get-BTC-right-now-02-10?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

udfdiw

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Oliver Brown (verified owner) –

We’re satisfied with the Plate Industrial Trolley. It has helped us organize materials more efficiently.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email: TRANSACTION 1,84671 BTC. GET >>> https://graph.org/Message–0484-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

jkm596

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✏ + 1.874938 BTC.GET – https://yandex.com/poll/5JjqQt7R61CTYdYVd17t6p?hs=53197ac2720001d4e6d37c711ed2aa26& ✏ (verified owner) –

68rrrn

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.469590 BTC.GET – https://yandex.com/poll/WDrLYhyq1Mc7jMHFgAW85q?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

jxh5jf

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket- Operation 1.320715 BTC. Get > https://yandex.com/poll/HYTE3DqXnHUqpZMyFqetue?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

8q400y

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

fxpav5 (verified owner) –

th8yhf

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email; Operation 1,440966 BTC. GET > https://graph.org/Ticket–58146-05-02?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

7j5brm

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a email # 193269. Go >> https://telegra.ph/Get-BTC-right-now-02-10?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

rs80st

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a transfer from our company. Gо tо withdrаwаl =>> https://telegra.ph/Ticket–9515-12-16?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

kr6feu

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.293204 BTC.NEXT – https://graph.org/Message–685-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

fvgqql

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification; Transfer NoTX00. ASSURE =>> https://telegra.ph/Ticket–9515-12-16?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

5bty7h

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

We send a transaction from unknown user. Next =>> https://telegra.ph/Get-BTC-right-now-01-22?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

l5k9j8

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.75573752 BTC.GET – https://telegra.ph/Ticket–6974-01-15?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

5ctj7j

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.756199 BTC.GET – https://yandex.com/poll/5JjqQt7R61CTYdYVd17t6p?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

slrksq

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Claim Free iPhone 16: http://wifimyrepublic.id/index.php?v7qi61 * * * hs=53197ac2720001d4e6d37c711ed2aa26* ххх* (verified owner) –

7jos7a

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder; SENDING 0.75198542 BTC. Continue => https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

bktqrl

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification: Operation 1,295263 BTC. Confirm >> https://graph.org/Message–0484-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

of8sd4

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.675297 BTC.NEXT – https://graph.org/Binance-04-15?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

vkbmzo

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Claim Free iPhone 16: https://www.championinterns.com/index.php?l3arn2 * * * hs=53197ac2720001d4e6d37c711ed2aa26* ххх* (verified owner) –

6ife44

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder: Operation 1.961574 BTC. Verify =>> https://graph.org/Message–17856-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

5ckz9y

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Get Free Bitcoin Now: http://wifimyrepublic.id/index.php?v7qi61 * * * hs=53197ac2720001d4e6d37c711ed2aa26* ххх* (verified owner) –

w89t7b

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✉ + 1.136512 BTC.NEXT – https://graph.org/Ticket–58146-05-02?hs=53197ac2720001d4e6d37c711ed2aa26& ✉ (verified owner) –

fl6x5d

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

✏ You have received a message(-s) # 137026. Open >> https://telegra.ph/Get-BTC-right-now-01-22?hs=53197ac2720001d4e6d37c711ed2aa26& ✏ (verified owner) –

aelfnr

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.675391 BTC.GET – https://graph.org/Message–05654-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

b0hin3

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification; Operation 1,521072 bitcoin. Get >>> https://graph.org/Ticket–58146-05-02?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

90wsh2

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.151765 BTC.NEXT – https://yandex.com/poll/Ef2mNddcUzfYHaPDepm53G?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

rr3gsm

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification; Process 0.75862319 bitcoin. Continue =>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

hph5aj

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Archie King (verified owner) –

The Plate Industrial Trolley is performing beyond expectations. It’s very durable and supports a lot of weight.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Message: Process 1,681488 BTC. Receive >>> https://graph.org/Message–04804-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

atxzg4

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.89090 BTC.GET – https://yandex.com/poll/76RuKke5vYn6W1hp2wxzvb?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

9vh7mb

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification; Operation 0.75391983 BTC. Get >>> https://telegra.ph/Get-BTC-right-now-02-10?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

7pyu4h

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Joseph Young (verified owner) –

We’re satisfied with the Plate Industrial Trolley. It has helped us organize materials more efficiently.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have received a message № 499649. Read > https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

4u13xp

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.659235 BTC.GET – https://graph.org/Binance-04-15?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

e1489y

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email; TRANSACTION 1,146003 BTC. Verify =>> https://yandex.com/poll/Ef2mNddcUzfYHaPDepm53G?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

oj0spu

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Lucas Turner (verified owner) –

The Plate Industrial Trolley is exactly what we needed. Strong, reliable, and holds up well.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Get Free Bitcoin Now * * * hs=53197ac2720001d4e6d37c711ed2aa26* ххх* (verified owner) –

6gx78w

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder; + 1.31685 BTC. GET > https://graph.org/Ticket–58146-05-02?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

fvpns2

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.303160 BTC.NEXT – https://graph.org/Ticket–58146-05-02?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

k3fv43

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 0.75312865 BTC.GET – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

hsstj1

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

* * * Snag Your Free Gift: https://www.championinterns.com/index.php?l3arn2 * * * hs=53197ac2720001d4e6d37c711ed2aa26* ххх* (verified owner) –

le7jln

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.54951 BTC.NEXT – https://graph.org/Message–05654-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

824zh6

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Lucas Turner (verified owner) –

The Plate Industrial Trolley was easy to install and is quite sturdy. Definitely built to last.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.209343 BTC.NEXT – https://graph.org/Message–0484-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

0v86od

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

You have a transfer from us. Assure >>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

qt3k5m

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Notification; You got a transfer NoPR45. GET >>> https://telegra.ph/Ticket–9515-12-16?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

06kjrk

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Archie King (verified owner) –

I’ve been using the Plate Industrial Trolley for several months now, and it has made our storage system much more efficient.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email- Withdrawing №GP83. Go to withdrawal => https://telegra.ph/Get-BTC-right-now-02-10?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

9bzsw6

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

⛏ Email: TRANSFER 1,797120 bitcoin. Confirm > https://graph.org/Ticket–58146-05-02?hs=53197ac2720001d4e6d37c711ed2aa26& ⛏ (verified owner) –

g5bz12

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email: Withdrawing NoZO16. GET >> https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

3eq9md

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

+ 1.985037 BTC.GET – https://graph.org/Message–04804-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

fvspfg

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Reminder- SENDING 1,8276 BTC. Assure => https://telegra.ph/Message–2868-12-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

95r417

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Email: Transaction NoGT03. GET => https://telegra.ph/Get-BTC-right-now-01-22?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

02ptr4

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Ticket: Process 1,70923 BTC. Verify > https://graph.org/Message–04804-03-25?hs=53197ac2720001d4e6d37c711ed2aa26& (verified owner) –

djuefh

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal