Equipment that

removes guesswork.

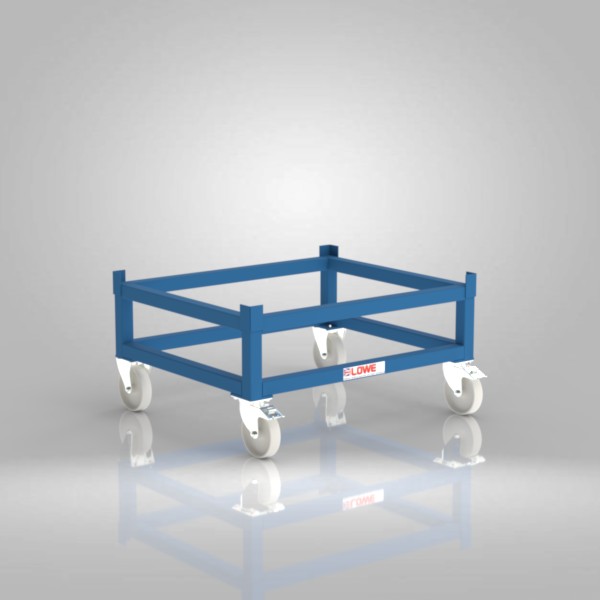

Material Handling Equipment for Operations at Scale.

When every minute on the floor counts, improvised kit costs time, money and safety. Our material handling equipment such as bulk bag holders, forklift attachments, tipping frames and engineered custom products replaces ad-hoc fixes with repeatable, documented solutions your crews can trust. Designs follow UK expectations for work equipment and where lifting applies, are supplied with the markings and paperwork your QHSE team needs.

Engineered for repeatability.

Operator-friendly.

Documentation ready.

-

Buy now This product has multiple variants. The options may be chosen on the product page£486.17 INC VAT, no hidden fees.£405.14 ex VAT

-

£428.96 – £652.55 INC VAT, no hidden fees.£357.47 – £543.79 ex VATRated 4.56 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£1,201.85 INC VAT, no hidden fees.£1,001.54 ex VATRated 4.73 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£1,184.53 – £1,434.66 INC VAT, no hidden fees.£987.11 – £1,195.55 ex VATRated 4.47 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£856.56 INC VAT, no hidden fees.£713.80 ex VATRated 4.53 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£927.11 INC VAT, no hidden fees.£772.59 ex VATRated 4.30 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£1,452.43 INC VAT, no hidden fees.£1,210.36 ex VATRated 4.31 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£1,135.92 – £1,802.98 INC VAT, no hidden fees.£946.60 – £1,502.48 ex VATRated 4.45 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£1,251.96 INC VAT, no hidden fees.£1,043.30 ex VATRated 4.44 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£1,063.24 INC VAT, no hidden fees.£886.03 ex VATRated 4.67 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£748.04 INC VAT, no hidden fees.£623.37 ex VATRated 4.53 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£775.33 INC VAT, no hidden fees.£646.11 ex VATRated 4.33 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£619.92 – £644.29 INC VAT, no hidden fees.£516.60 – £536.91 ex VATRated 4.50 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

-

£526.43 – £957.73 INC VAT, no hidden fees.£438.69 – £798.11 ex VATRated 4.46 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£541.79 – £986.35 INC VAT, no hidden fees.£451.49 – £821.96 ex VATRated 4.38 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£827.59 – £851.95 INC VAT, no hidden fees.£689.66 – £709.96 ex VATRated 4.38 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£482.04 INC VAT, no hidden fees.£401.70 ex VATRated 4.63 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£2,995.92 – £3,020.28 INC VAT, no hidden fees.£2,496.60 – £2,516.90 ex VATRated 4.35 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£1,428.10 – £1,805.78 INC VAT, no hidden fees.£1,190.08 – £1,504.82 ex VATRated 4.30 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£1,043.81 – £1,478.92 INC VAT, no hidden fees.£869.84 – £1,232.43 ex VATRated 4.61 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£406.43 – £658.58 INC VAT, no hidden fees.£338.69 – £548.82 ex VATRated 4.29 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£377.54 – £641.40 INC VAT, no hidden fees.£314.62 – £534.50 ex VATRated 4.56 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£644.70 INC VAT, no hidden fees.£537.25 ex VATRated 4.63 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£425.24 – £787.52 INC VAT, no hidden fees.£354.37 – £656.27 ex VATRated 4.50 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£406.43 – £596.76 INC VAT, no hidden fees.£338.69 – £497.30 ex VATRated 4.59 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£457.03 – £851.62 INC VAT, no hidden fees.£380.86 – £709.68 ex VATRated 4.50 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£404.94 – £663.88 INC VAT, no hidden fees.£337.45 – £553.23 ex VATRated 4.47 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£447.30 – £728.45 INC VAT, no hidden fees.£372.75 – £607.04 ex VATRated 4.50 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£406.74 – £681.04 INC VAT, no hidden fees.£338.95 – £567.53 ex VATRated 4.37 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£430.52 – £776.77 INC VAT, no hidden fees.£358.77 – £647.31 ex VATRated 4.20 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£532.84 – £884.93 INC VAT, no hidden fees.£444.03 – £737.44 ex VATRated 4.45 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£831.04 – £1,157.36 INC VAT, no hidden fees.£692.53 – £964.47 ex VATRated 4.47 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£1,540.32 – £1,701.12 INC VAT, no hidden fees.£1,283.60 – £1,417.60 ex VATRated 4.73 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

-

£866.41 – £890.77 INC VAT, no hidden fees.£722.01 – £742.31 ex VATRated 4.64 out of 5Buy now This product has multiple variants. The options may be chosen on the product page

Purpose-built fixtures that remove uncertainty from daily moves.

Purpose built fixtures that remove uncertainty from daily moves.

From controlled discharge of FIBCs to fork-secure transport of awkward loads, we size frames and attachments to your routes, loads and truck fleet. That means clean fork entry, positive retention, labelled faces and consistent footprints, so shifts flow faster, incidents go down and audits pass with less friction.

How we build for compliance and what your team must document.

Topic

Applies to

What we supply

Marking/ID on unit

Your duty (site)

UKCA conformity

Products in GB market

UK Declaration of Conformity (on request)

UKCA mark (visible, legible, indelible)

Keep DoC accessible for authorities

PUWER

All stillages used as work equipment

Safe-use guidance

Product ID / serial

Ensure equipment is suitable, maintained, staff trained

LOLER (lifting)

Stillages with lift points/eyes, crane use

Examination/test record (where applicable)

SWL plate; serial

Plan lifts; appoint competent person

Load information

All stillages in service

SWL on plate

SWL permanently on unit

Provide weight info where practicable

Traceability

Fleet/asset control

Serial register format

Serial/asset tag

Keep inspection history per serial

The business case is clear.

Safer, standardised handling reduces risk and delays; documentation keeps audits calm.

workers sustained a self-reported non-fatal injury in 2023/24 — engineered MHE helps remove risky improvisation.

million working days were lost to work-related ill-health & non-fatal injuries in 2023/24 — small handling wins add up fast.

of employer-reported non-fatal injuries in 2023/24 involved handling, lifting or carrying, exactly where fit-for-purpose frames and attachments pay back.

is the estimated annual cost of workplace injury and new work-related ill health (baseline 2022/23) — prevention pays.

Frequently Asked Questions

Bulk bag (FIBC) holders, fork sleeves/extensions, bump stops & guides, tipping frames/cradles, drum/coil handlers, liftable frames/accessories, and engineered “specials” designed around your SKU, route and truck fleet.

Operations that need repeatable, documented equipment at scale—3PLs, manufacturers, recyclers, food & bev packaging, utilities—rolling out across one or many UK sites.

Where applicable, yes. We also provide ID/SWL plates and serials as standard practice. For lifting accessories/frames, we supply examination/test evidence as required so your competent person can maintain the technical file.

We design for PUWER (work equipment suitability, safe use, maintenance). Where an item is used for lifting, we align to LOLER expectations and supply the relevant documentation (e.g., exam/test record) so your competent person can plan inspections.

Yes. We tune fork pocket size and chamfer, sleeve/extension length, bump-stop positions and turning clearances to your trucks, tine profiles, aisle widths and floor conditions.

SWL is defined at design/verification and, where applicable, by test. It’s shown on a durable plate on the unit and recorded in the documentation we supply.

Treat MHE as work equipment under PUWER: pre-use checks and periodic inspections. For lifting accessories/frames, arrange thorough examinations at intervals set by your competent person (often 6 or 12 months depending on the item/use scheme).

Yes. We provide 2D/3D approval drawings; for specials, we can prototype or pilot before full rollout. We can also supply simplified operator diagrams/labels for training packs.

Yes. We engrave/emboss ID plates, apply barcode/QR labels, or accommodate RFID tags. We’ll supply a serial register (CSV) for your asset system.

We size frames to spout height, chute angle, hook spacing and hopper geometry, and can add tie-points, dust cuffs, splash guards, and sight/level windows as required.

We design sleeves with fitment tolerance and retention pins to protect forks, and specify use guidance. Training and correct fitment are essential; never exceed the marked SWL/length guidance.

Yes. We can add locking mechanisms, controlled release, two-hand interlocks, guards and warning labels; we’ll align the spec to your risk assessment and product flow.

Yes. We build V-block cradles, curved saddles, lined contacts, strap points and poka-yoke features so operators place and secure loads the same way every time.

Powder-coat is standard; options include zinc-rich primers, hot-dip galvanising for outdoor/corrosive use, and stainless components where needed. We discuss environment, chemicals and washdown before sign-off.

Site training remains your responsibility. We can supply use/maintenance notes, labels and simple SOP visuals for inclusion in your training packs and toolbox talks.

We standardise geometry, colours, labels and documentation, then serialise by site, provide spares/spec packs, and coordinate delivery schedules against your go-live plan.

Share equipment specs (clearances, sensors, lift methods). We’ll align footprints, pickup points and label faces to your AMR/AGV/rack/shuttle interfaces and validate with trial units if required.

Yes, subject to inspection. We can straighten, replace components, re-label and re-finish. If a structural repair could affect SWL, we’ll advise on re-inspection before return to service.

Yes. Plates, labels, straps, pins, fasteners, bump stops and touch-up finishes—matched to your approved spec so fleets don’t drift over time.